With the heavy focus on choosing environmentally friendly and recycled materials in various industries, we at Målbar have sought to remind you that using recycled materials won’t solve the climate crisis alone. Now that that’s settled, recycling and moving towards a circular economy is part of the solution. And for a product to be fully circular, you must be able to take it apart in the main materials. In other words, the product must be designed for disassembly.

This means to incorporate a disassembly function in all assembly points. For example:

- You avoid the use of glue between components such as upholstery and seat or textile.

- You use ordinary screws and bolts, that can be removed with ordinary tools.

- You use pure materials since most mixed materials are hard or even impossible to recycle.

When a product can be easily disassembled, it is more likely to end up in the different fractions of waste allowing for the materials to be recycled. And for some materials, it can have a significant impact on the climate emissions.

Balancing Contrasts

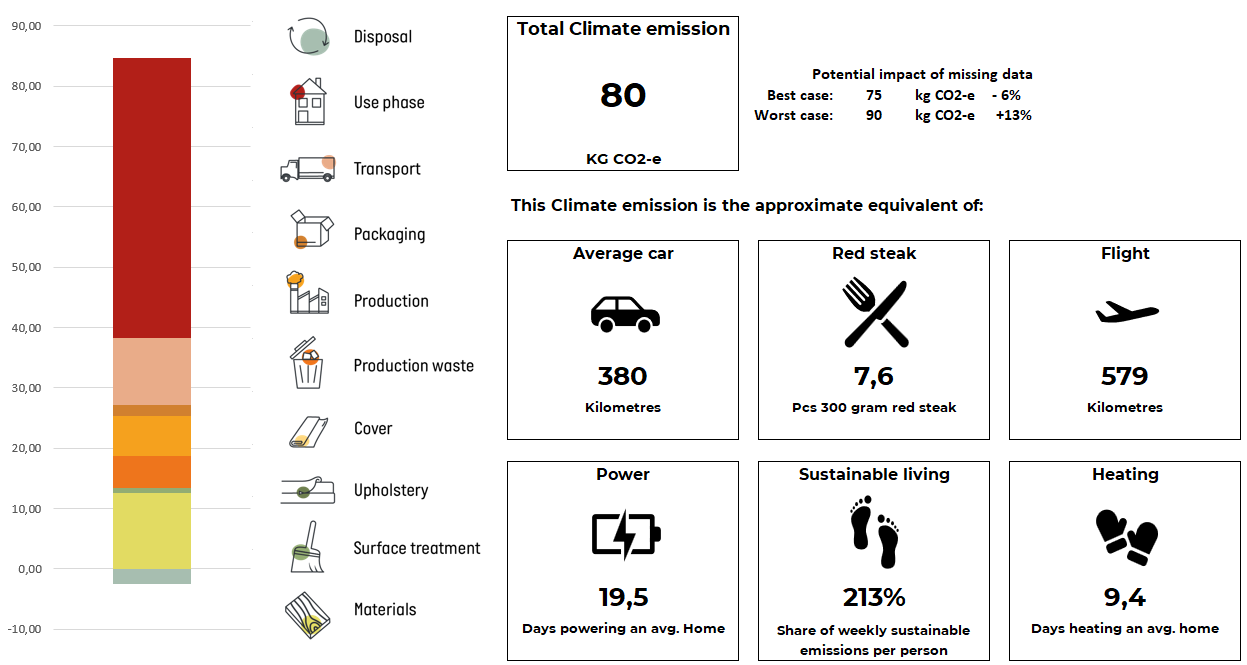

Let’s use our stool project as the case of example. As part of a larger cooperation initiated by The Circular Furniture Network between Målbar, The Upcycl and 6 design companies, 13 creative stools were created from the same basics. Målbar calculated on all the stools in a reused and a virgin version to see the difference in climate impact. Version 13 – Balancing Contrasts – is a multifunctional lamp table made from pine wood, steel tubes from wheelbarrow production, and recycled paper.

This version is interesting in a design for disassembly perspective because of its metal parts and electronic parts.

In a product screening, you will see that because the metal parts are registered as ‘designed for disassembly’, the disposal phase – which usually is found at the top of the climate bar – now is placed in the bottom below the zero line. This is because metals in fact have a well-established and well-working recycling chain, due to it being a highly valued and limited resource.

The reason is that metals can be remelted, and they keep almost all their qualities in contrast to other materials that might lose strength and durability during their recycling process. This means that most metals are 100% recycled given that they are removed from whatever they were attached to and sent to recycling. This gives you a climate credit.

For many other materials, the story is quite different. We do not yet have sufficient recycling chains for wood, plastic, or textile that are more than or equally efficient to the virgin production. Furthermore, though it might be possible to recycle, the climate benefit might not be significant. This is often the case for plastics. While for metals, the virgin production far exceeds the recycling production in complexity and climate impact. That’s why PEF gives credit only for recycling metals. For now!

Designing electronic parts for removal

Furthermore, it is very important that electronic parts can be removed from a product such as the lamp table at the end-of-life phase. Electronic parts contain a relatively large amount of rare metals. Even though they can be very hard to disassemble, there are somewhat established procedures for recycling electronics. Usually, if the electronic parts are removed from other materials, they can be crushed entirely, so that the different metals can be collected and reused or recycled.

WEEE is EU’s and the member states’ rules on Waste of Electric and Electronic Equipment. In short, this decree states that one must contribute to the safe and suitable disposal of equipment, when the consumer gets rid of it. It applies to all companies that produce and sell electric and electronic equipment and it requires companies to register in all countries in which they distribute or sell equipment and to report on sold equipment. Most importantly, you are obligated to finance and organize the collection, management, recycling, and reuse of your products.

The WEEE decree encourages companies to design electronics to be easily removed from the appliances they are part of.

Designing for repairing

Another important result of design for disassembly is also that the product will be designed for reparations. So, when designing for disassembly, you should also think of making spare parts available for your products, so that consumers can repair it instead of throwing the whole product away.

If you’re not already thinking in or practicing design for disassembly, you can start by assessing your primary products as well as your electric or electronic products. This is where you can make the biggest difference. And then look at the primary components of these products. How are they assembled? Are there any metal or electric parts of significant size? Are the materials recyclable? Pure materials have the best recycling potential, so if you currently use many mixed materials, you might consider whether alternative materials could be an option in your designs. How can you make it easier to unmake and recycle your products?