Bly Studio, furniture designers

Bly Studio is founded by two young female designers, Eva Fly and Anne Brandhøj. With a common background as furniture designers from The Royal Academy of Design in Copenhagen, Eva and Anne work to create a strong sense of functionality and memorable visual expressions.

“It is motivating to have a receiver”

Anne and Eva like the blind date concept. They appreciate the opportunity to work with something concrete with a receiver at the end. They feel that this set-up gives them a possibility to show their ambitions to make responsible and conscious designs.

Their brief describes a wish for a movable in-between furniture piece that requires a high degree of stability. This is a furniture category, that Bly Studio hasn’t work with before, but Eva and Anne are excited to work with this new challenge. And they are eager to create a design that will please the company. Still, they hope to surprise them with their shape and material choices.

Reducing the amount of material while ensuring stability

From our point of view, the most difficult aspect of this design is to stay true to the overall theme of reduction. Not that we don’t want to – we work really hard to minimize the climate footprint of our design. But the high demand for stability in this product means that we must make a strong, durable, and solid construction”.

Nevertheless, the two designers examine each element of their design to find out how much they can reduce the amount of material. They are designing for disassembly, and they use Målbar’s screening tool to make some of their material choices based on climate emissions. They believe the tool can serve as argumentation for some of their design choices, which they see as a valuable support in their communication towards the company providing the brief.

Usually these projects that we have once a year with Danish Design Makers, they do not have a specific receiver, but only a theme. It is motivating to have a receiver at the end. It can be a challenge to get in contact with the big brands, especially the foreign companies. In this project we get the chance to create something for someone specific without being judged beforehand.”

This article reflects the designer’s own opinion and Målbar does not necessarily agree with their statements about materials, processes, etc.

Climate calculations and insights

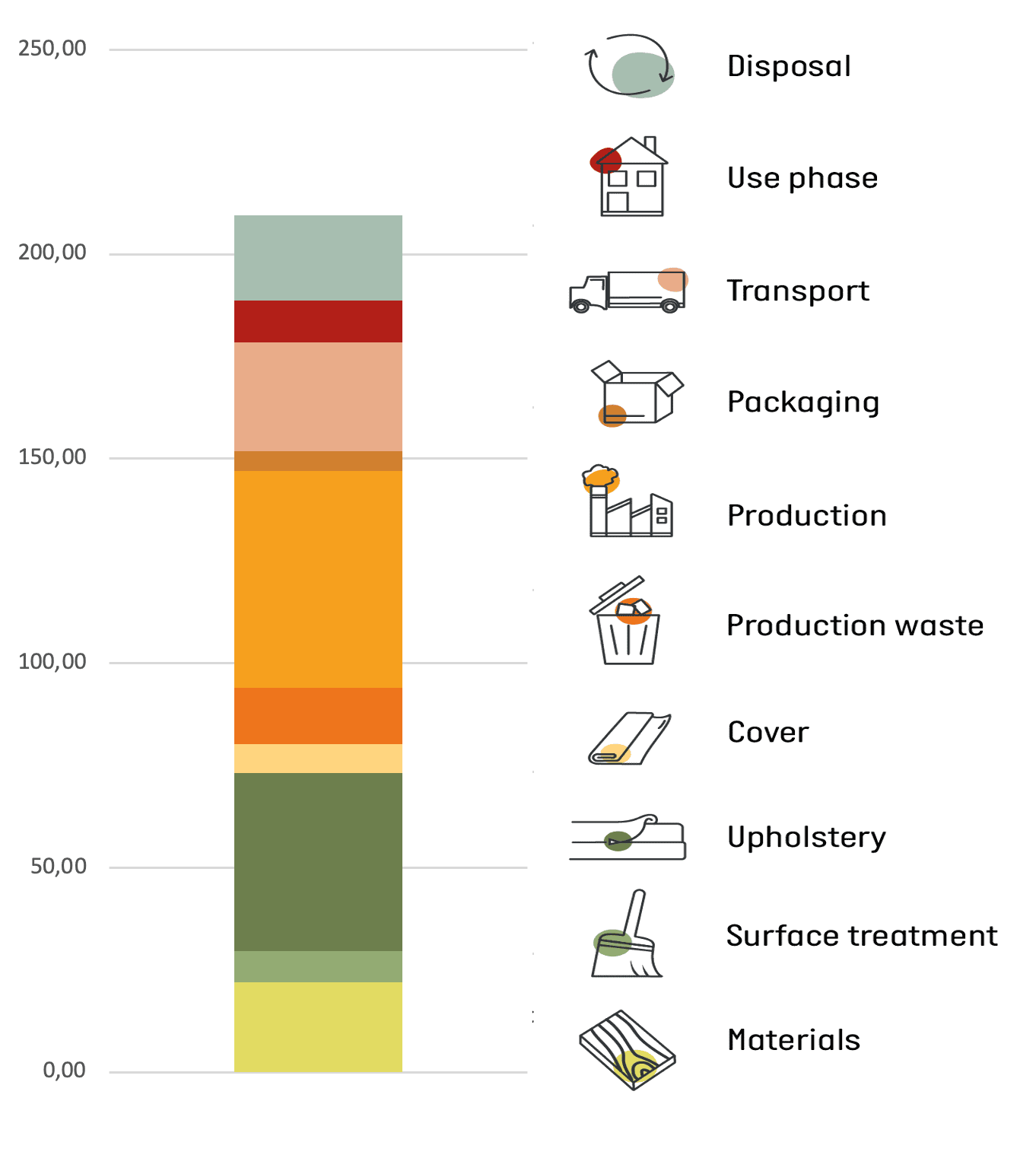

Bly Studio’s in between sitting and standing piece of furniture is called Soft Angles and have an estimated climate impact of 210 kg of CO2eq.

The choice to design for disassembly is especially good for lowering the emissions from the visible metals in this design, because these are ensured to be recycled. The metal structure inside the upholstery is not assumed to be recycled at end-of-life since these components aren’t visible and thus we assume that they won’t be noticed at the product’s end-of-life.

In EU, there aren’t established effective recycling systems for the other materials in Bly Studio’s design (plywood board, solid wood, foam, polyester wadding, and polyester textile), meaning that from a climate perspective, these materials don’t benefit from being designed for disassembly yet. Hopefully, this will change for the better in the future, hence Målbar still encourages designers to design all parts for disassembly.

The choice of solid wood as the carrying structure of the panels is a good choice because the panels are made lightweight by adding honeycomb paper cores.

The result is a low weight piece of furniture of 40kg, which proves the successful reduction of material weight.

The thoughtful choices of material and low weight of the total solution have resulted in emission reductions. PU foam is now the most emitting proportion of the design. Further reductions should be focused on reducing the amount of foam or replacing it with less emitting alternatives. Foamed EVA could be an option, since it has lower weight and is recyclable in contrast to PU foam.

Photo by Kristine Funch

Explanation of climate bar

The climate bar shows how the emissions from the design are distributed between 10 sources within the product life cycle. Here you can see that the largest part of the climate footprint stems from the production phase. This is mostly due to the manufacturing of textile and foam. Another significant part of the emissions originates from the nearly 8 kilograms of upholstery foam and wadding.

There are emissions from the use phase on all products, because of the waste that is generated from returned products from consumers.

Assumptions

- The solid wood manufacturing waste is estimated equal to the weight of the finished component

- The amount of solid wooden board manufacturing waste is estimated to be 15%.

- The amount of metal tube manufacturing waste is assumed to be 2% as the tube is only attached in to ends.

- The amount of upholstery waste – like foam and wadding – is assumed to be 10% because of the straight rectangular shapes needed.

- The amount of textile cutting waste is estimated to be 10%

- We assume that metals, plastics, and textiles are produced according to the global average unless we know differently. All other materials are assumed to be produced in the EU

- We assume a transport distance by lorry from supplier to warehouse of 1,000 km

- We assume a transport distance from warehouse to final client of 1,000 km

Målbar builds their assumptions on their experience with industrial production and LCA’s on manufacturing companies.

Context

Målbar participates in Danish Design Makers‘ 2024 design challenge, The Blind Date experiment where 19 designers and design duos answer furniture briefs from anonymous European furniture companies. The designers use Målbar’s cllimate screening tool to gain insigths into the climate emissions of materials and production processes, learning about the climate impact of their design choices. Ultimately, the total cliamte footprint of each design will be calculated and presented at ORGATEC in Cologne on October 22nd-25th 2024.