Steffensen & Würtz, furniture design

Pia Würtz and Thomas Steffensen run a design studio together called Steffensen & Würtz. This is their first time exhibiting with Danish Design Makers.

Waste is a resource

Thomas and Pia have thought far and wide in the beginning of their design process considering many different designs and materials. First, they wanted to make something in steel, because of the efficient recycling systems which ensure that most steel is recycled. But they discovered in the Målbar tool that it still has a significant climate impact. Then they completely changed direction and went with a wooden product. They also experimented with the idea of having a transparent design where all parts would be visible but discarded this idea because of hygiene reasons.

They can read from their brief that their company is an experienced upholstery specialist, so they feel they have to bring some softness into their design as well.

“We really want to please our blind date. But it is also a little conflicting for us with the upholstery because we’re eager to make a design with a low climate footprint.”

So, Pia and Thomas have been working with leftover materials, also called new waste. This is a bit of a challenge since the nature of the blind date prevents them from finding out how the company’s production waste looks like.

We will suggest to them how they can use their own left-over materials in their production of our design. And we hope we can inspire them to see that it is possible to obtain high comfort and good bounce effect with less material, waste materials, and intelligent design.”

Designer customized climate tool

Pia and Thomas find Målbar’s climate screening tool beneficial and have used it from the beginning of their process. They have used it to select which tree species they wanted to use, and they have also investigated the many different types of surface finish.

We think it is a good tool because it provides us with arguments for our choices. And it is interesting so see the actual difference in emissions from different materials. The tool creates a helpful structure for working with reduction.”

Thomas and Pia also stress the fact that the tool becomes better the more experience you have with it. They agree that they would benefit from having a customized designer version of the tool, that could support them in their daily work to minimize the climate impact of their designs.

The blind date is the challenge, the reduction theme is the learning

The energetic design duo finds the blind date concept a little frustrating but also fun.

We talk about reduction. And then we are creating a design without having any idea of whether it has a legitimate place in the world. We spend resources on developing something without knowing if the company we’re making it for will have it. However, we do hope to inspire them to be a little greener – but again, we know nothing about how far they are in their green transition.”

Trying not to figure out who their company is, Pia and Thomas focus on the reduction theme and the collaboration with Målbar. They have worked to minimize the amount of material and have created comfort in a minimalistic way. They have designed their product for disassembly and to be flat-packed.

If they didn’t have to think about designing for a potential customer, they feel that they would have been able to experiment much more with their design, working more creatively with the reduction theme. However, this creative duo believes they have found purpose in their design and have stayed true to their design philosophy.

This article reflects the designers’ own opinion and Målbar does not necessarily agree with their statements about materials, processes, etc.

Climate calculations and insights

Pia and Thomas have designed two versions of their wooden lounge chair called Nook Chair; one with armrest and a cushion and one without.

The version with armrest and cushion has an estimated total climate impact of 65 kg CO2eq, while the one without cushion and armrests has an estimated total climate impact of 32 kg of CO2eq.

The reduction choices in this design are wood materials instead of steel, no upholstery foam, low emission surface treatment, and flat packing. All of these provide significant reductions.

The footprint of this product is very well reduced. For further reduction of the version with cushion, we propose to exchange the high amount of polyester wadding with kapok – which could reduce emissions by 15%. For the version without cushion, it will be difficult to reduce it further without making a different design.

Photo by Kristine Funch

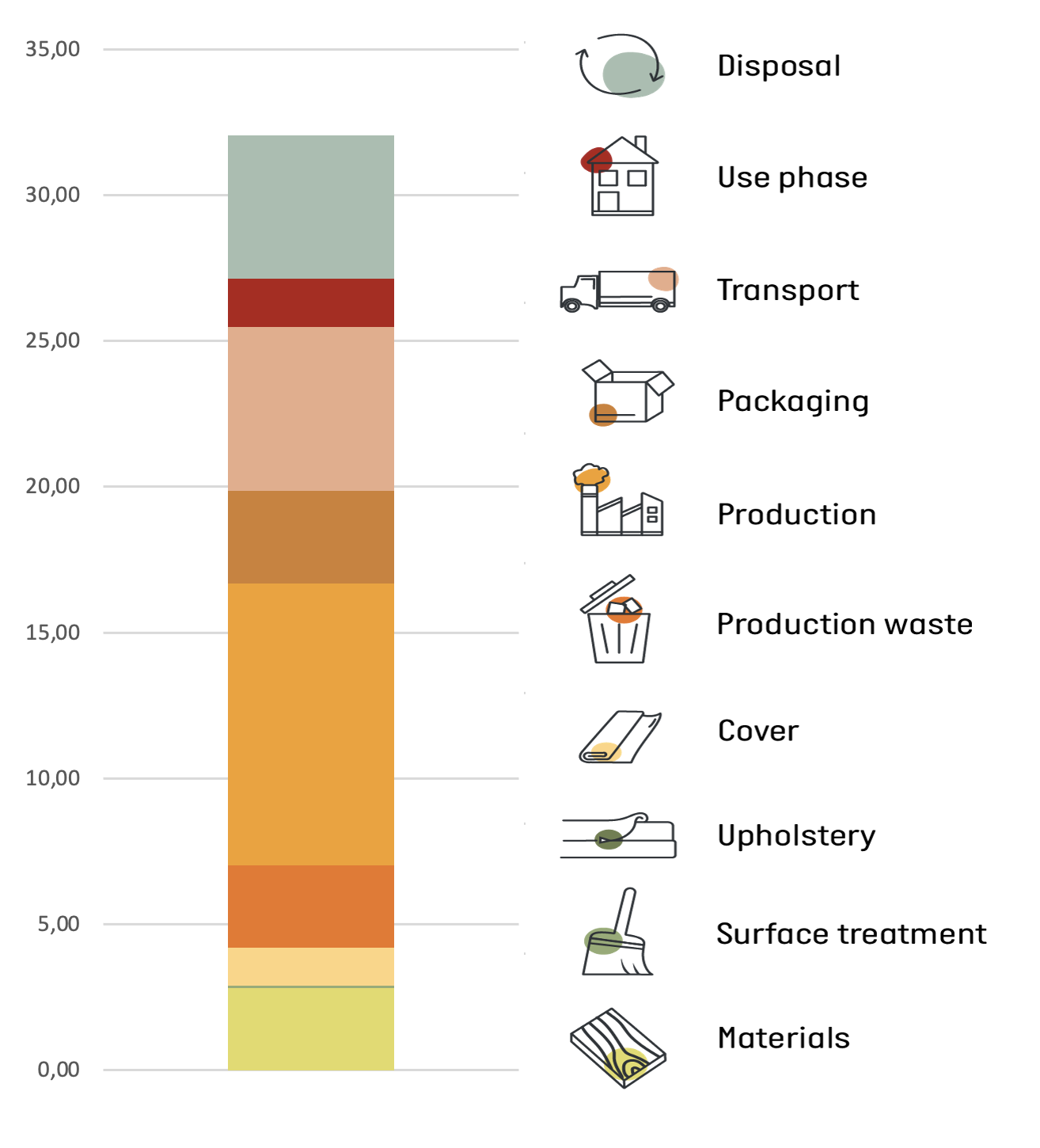

Målbar climate bar of naked version

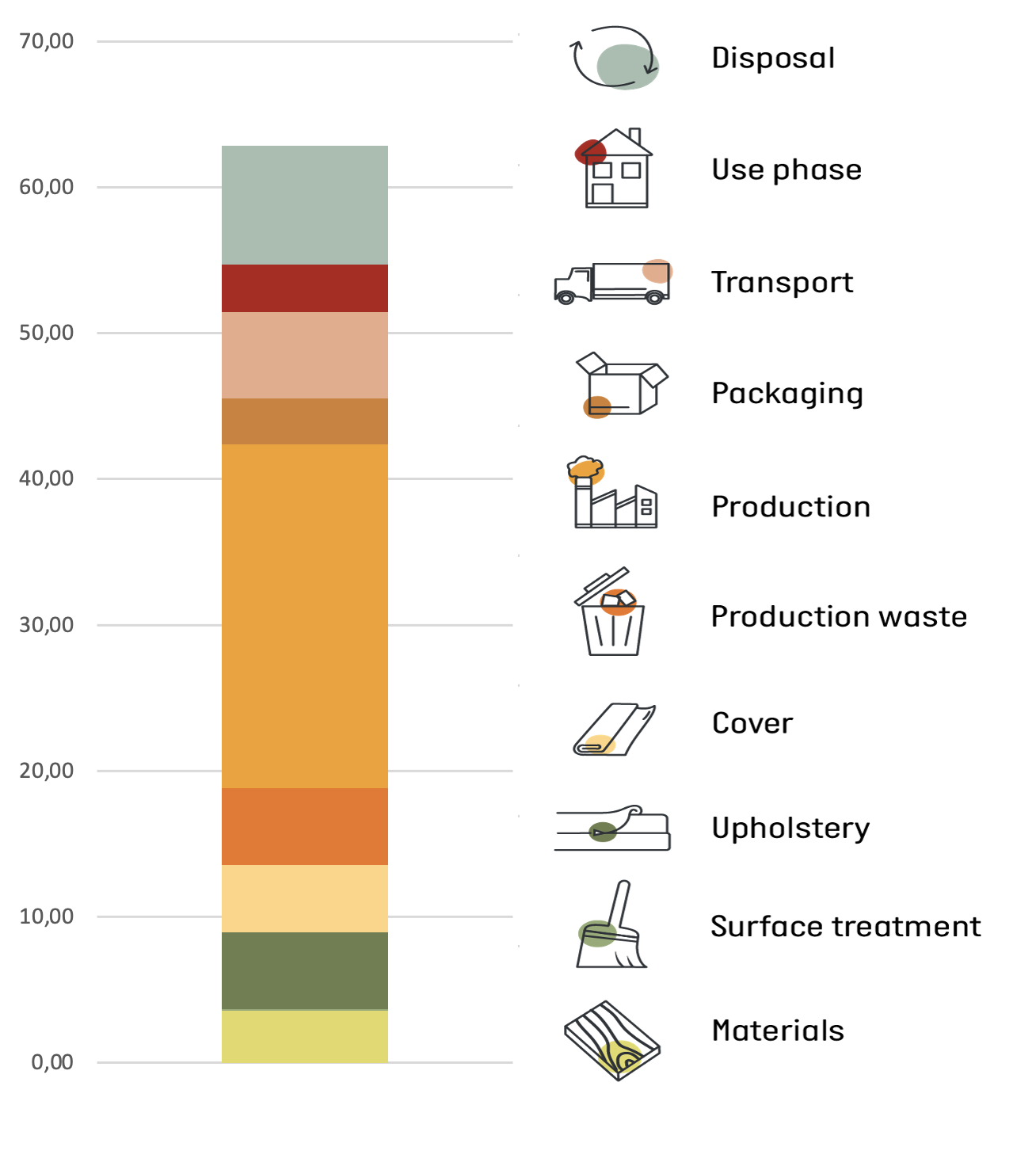

Målbar climate bar of cushion version

Explanation of climate bar – naked version

The climate bar shows how the emissions from the design are distributed between 10 sources within the product life cycle. Here you can see that the biggest share of the footprint comes from the production phase. This is due to the manufacturing of the textile that constitutes the seat and back of the lounge chair. Next, you notice the transport emissions take up a large part of the footprint, because of the amounts of air shipped when transporting large volume furniture.

Explanation of climate bar – cushion version

The major difference is the upholstery part which also makes the production phase raise in this version. Furthermore, it looks like the transport emissions are lower, but they are actually a little higher. Only they constitute a smaller part of the total emissions.

There are emissions from the use phase on all products, because of the waste that is generated from returned products from consumers.

Assumptions

- The manufacturing waste of the solid wood components is estimated to be the same as the finished component.

- The amount of textile cutoff waste is estimated to be 15%.

- We assume that metals, plastics and textiles are produced according to the global average unless we know differently. All other materials are assumed to be produced in the EU

- We assume a transport distance by lorry from supplier to warehouse of 1,000 km

- We assume a transport distance from warehouse to final client of 1,000 km

Målbar builds their assumptions on their experience with industrial production and LCA’s on manufacturing companies.

Context

Målbar participates in Danish Design Makers’ 2024 design challenge, The Blind Date experiment where 19 designers and design duos answer furniture briefs from anonymous European furniture companies. The designers use Målbar’s climate screening tool to gain insigths into the climate emissions of materials and production processes, learning about the climate impact of their design choices. Ultimately, the total climate footprint of each design will be calculated and presented at ORGATEC in Cologne on October 22nd-25th 2024.