Steffen Juul,

furniture designer

Steffen Juul is an experienced furniture designer and has been a member of Danish Design Makers for about 10 years, participating in 3 exhibitions with them all over the world.

Outdoor furniture moves indoors

Steffen finds his brief from the anonymous company inspiring, well described, and comprehensive. He hasn’t made this type of furniture before, so he thinks it is an interesting and challenging task.

On the other hand, Steffen is used to working with briefs as such, though he usually seizes the opportunity to communicate with the company that has set the task.

“It is a complex design I’m making. It has to be modular and work in public and semi-public waiting spaces, but I also want my design to be able to stand alone. I haven’t seen this type of furniture indoor before, only outside.”

Thus, Steffen has worked to solve many functionalities simultaneously. But this hasn’t prevented him from peaking at the Målbar tool at the early stages of his design process. He wants to optimize his design in the name of reduction and plans to use the screening tool later in his process as well.

My primary focus is to make something that can be sold, to be honest. This might very well go hand in hand with a lower climate footprint, but there is a big ship to be turned. People’s focus and habits don’t change overnight, and it’s challenging to figure out how far you can go in the reduction direction and still make products that sell.”

Steffen’s focus is also on how he can make a design that is able to be renewed easily. This has resulted in a design where the fabric can be changed and thus modify the expression of the product.

“It is not all furniture that are suitable for having their covers changed, but those that are – and more and more furniture is designed this way – are bound to have a certain look. I think we need to cherish and protect our artistic liberty to avoid that everything will look identical.”

Steffen hopes that in the future, companies and designers make it easy for consumers to like the products that are designed and made responsibly and with a lower climate footprint by making conscious choices from the beginning in all new product development.

Bringing people and knowledge together

Steffen finds the blind date experiment quite exciting.

It is a great way to bring people together, to bring designers and companies together, and to bring knowledge together by including Målbar in the project”, he says.

To Steffen, working so intensely with the climate footprint of his design is an eye opener. To consider every element of his design from a climate perspective and to constantly stay critical towards his ideas is an interesting experiment for him.

Overall, Steffen finds the project very interesting and thinks it has the potential to move some boundaries in the industry. Personally, he has learned a lot.

“The awareness and communication about the blind date concept and the theme is what is most important here. It is the project as a whole that matters, not my individual product. My design will not change the world, but it might change me though”.

Steffen commends DDM for their ability to create such a comprehensive project that is both fun and social while also being ambitious, well-structured, and professional.

This article reflects the designer’s own opinion and Målbar does not necessarily agree with their statements about materials, processes, etc.

Climate calculations and insights

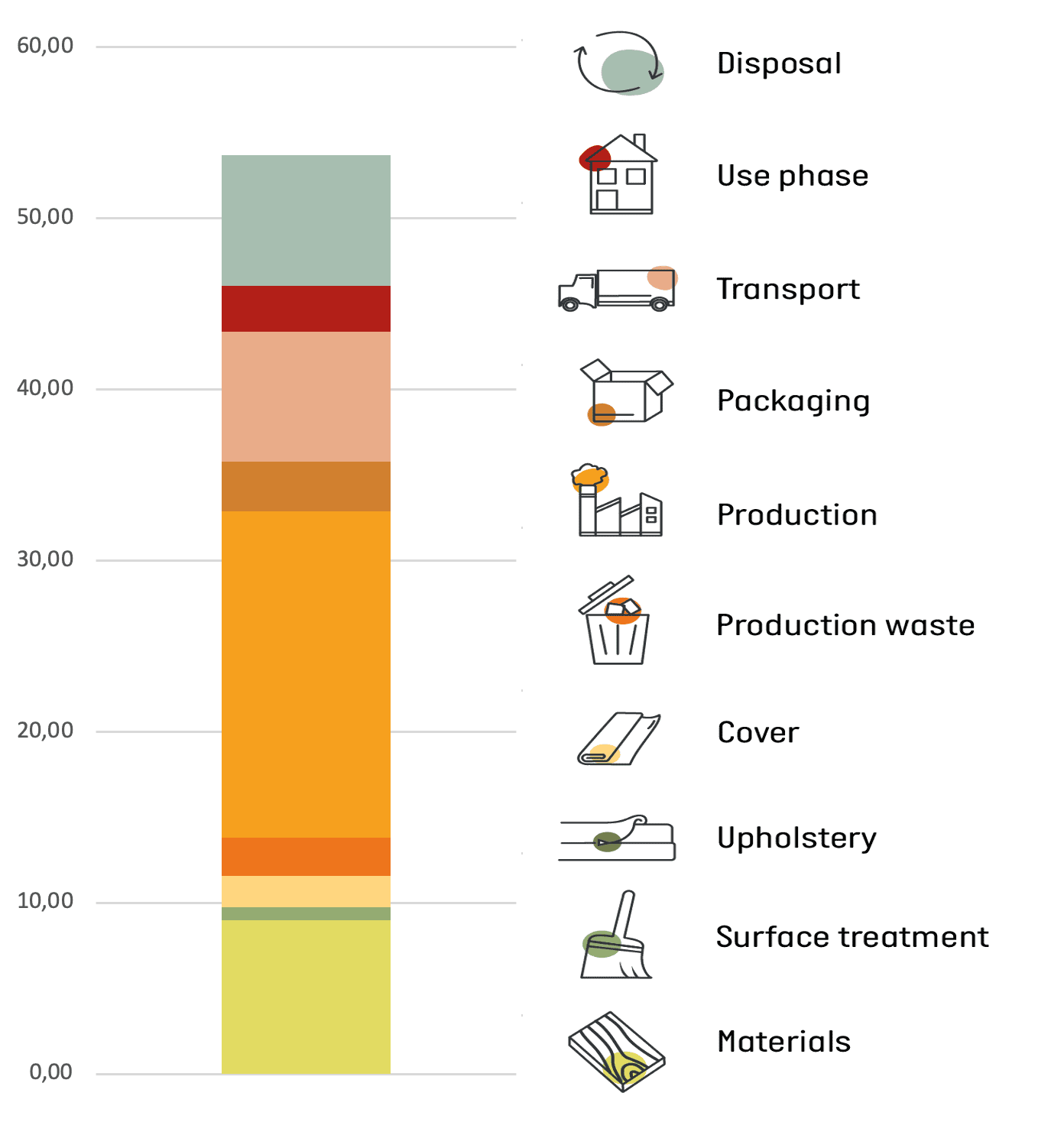

Steffen’s in between sitting and standing piece of furniture is named GoBuk and has an estimated total climate emission of 55 kg of CO2eq.

Steffen has aimed for a simple design language that can be easily renewed with the changing trends. Unfortunately, we are not able to calculate a possible longer lifetime of this.

The choice of EVA foam instead of PU foam provides a reduced footprint. EVA foam is an elastic thermoplastic. It means that it can be recycled at end-of-life in opposition to PU.

The final result is a lightweight piece of furniture which effectively reduces its emissions.

The emissions can be further reduced if cotton is replaced by organic cotton. But the reduction is small – around 2% – because most textile emissions come from the electricity consumed in production.

Photo by Kristine Funch

Explanation of climate bar

The climate bar shows how the emissions from the design are distributed between 10 sources within the product life cycle. Here you can see that the biggest impact originates from the production process. In this case, it is the production of textiles that contribute with high emissions, because textile undergo many energy consuming processes – like spinning, weaving and dyeing – before their final form. Furthermore, the transport carries a significant part of the climate impact, because GoBuk is quite voluminous and cannot be flat-packed. It’s size results in a large box that takes up a lot of space in the transport and hereby make the full load transport less efficient.

There are emissions from the use phase on all products, because of the waste that is generated from returned products from consumers.

Assumptions

- The molded plywood components are assumed to have only 5% manufacturing waste as they are rectangular and utilize the veneer sheets well

- The upholstery foam is assumed to have 15% cutting waste, while the textile is assumed to have 20% cutting waste

- Målbar assumes that metals, plastics, and textiles are produced according to the global average unless we know differently. All other materials are assumed to be produced in the EU

- We assume a transport distance by lorry from supplier to warehouse of 1,000 km

- We assume a transport distance from warehouse to final client of 1,000 km

Målbar builds their assumptions on their experience with industrial production and LCA’s on manufacturing companies.

Context

Målbar participates in Danish Design Makers’ 2024 design challenge, The Blind Date experiment where 19 designers and design duos answer furniture briefs from anonymous European furniture companies. The designers use Målbar’s climate screening tool to gain insigths into the climate emissions of materials and production processes, learning about the climate impact of their design choices. Ultimately, the total climate footprint of each design will be calculated and presented at ORGATEC in Cologne on October 22nd-25th 2024.