Thomas Albertsen,

industrial designer

Thomas Albertsen is educated from the Danish Design Academy in 2007 and is one of the founding members of Danish Design Makers.

If you are in control of your design process, there’s nothing you cannot create

Thomas’ brief is very short but does reveal the wish for an upholstery furniture piece. Thomas has never really been involved in designing this kind of furniture, but he appreciates the challenge of this experimental project.

”I always approach my design process the same way. But in this case, my point of departure has been the workshop by Målbar about how to reduce the amount of material and the factors that influence the climate emissions the most.”

Thomas has had many loose ideas in the beginning slowly narrowing them down to his final solution. He has designed a hollow element that is covered by a new textile that is heat treated to make it shrink. This is supposed to eliminate the need for any foam parts, as this textile is self-carrying and thus creates the seat and back rest.

I want my design to resemble an upholstered furniture piece without being filled with foam. Usually, I’m against things that look like something they’re not. But this case feels different. Because I have created this voluminous shape without foam, but with the same comfort.

Control equals flexibility

Thomas is used to making his own prototypes in his workshop. But since he’s not too experienced in making upholstered furniture, he considered having a professional upholsterer attach the textile to his prototype. However, he chose to do it himself to avoid losing control over the process.

“It would be easy to have a professional to do the job, but if something goes wrong, that person wouldn’t be in a position to decide the next step. By doing it myself, I keep the overview of all processes and that means I can be more flexible in my design choices.”

Målbar takes practice

Thomas hasn’t used Målbar’s climate screening tool actively in his process, but he intends to let it help him decide which material his inner construction should be made of. He wants to communicate about different possibilities and use emission numbers as arguments for choosing one over the other.

I must practice using Målbar’s tool, before I can integrate it more actively in my work. But because Målbar is part of this project, I am always aware of the reduction task, and it serves as a good reminder. I think the tool is especially good as argumentation for one’s design choices. And to examine the climate emissions of materials I don’t know much about.”

Blind date creates connections

Thomas reflects upon the benefits of this project. He points out that the companies get the opportunity to experience the work of designers, they didn’t know before. And hopefully, they will see the potential in collaborating with designers that don’t have a big name in the industry or that haven’t designed a classic yet.

”I think too many companies choose their designers by their name or their reputation in the industry. But this makes it hard for new designers to get recognized. Most people outside the business rarely know the name of the designers behind most furniture apart from a few of the most well-known classics. So, maybe it is not that important for companies to work with a well-known name. And I hope these companies will understand that there are many skilled, innovative, and brave designers they could team up with.”

This article reflects the designer’s own opinion and Målbar does not necessarily agree with their statements about materials, processes, etc.

Climate calculations and insights

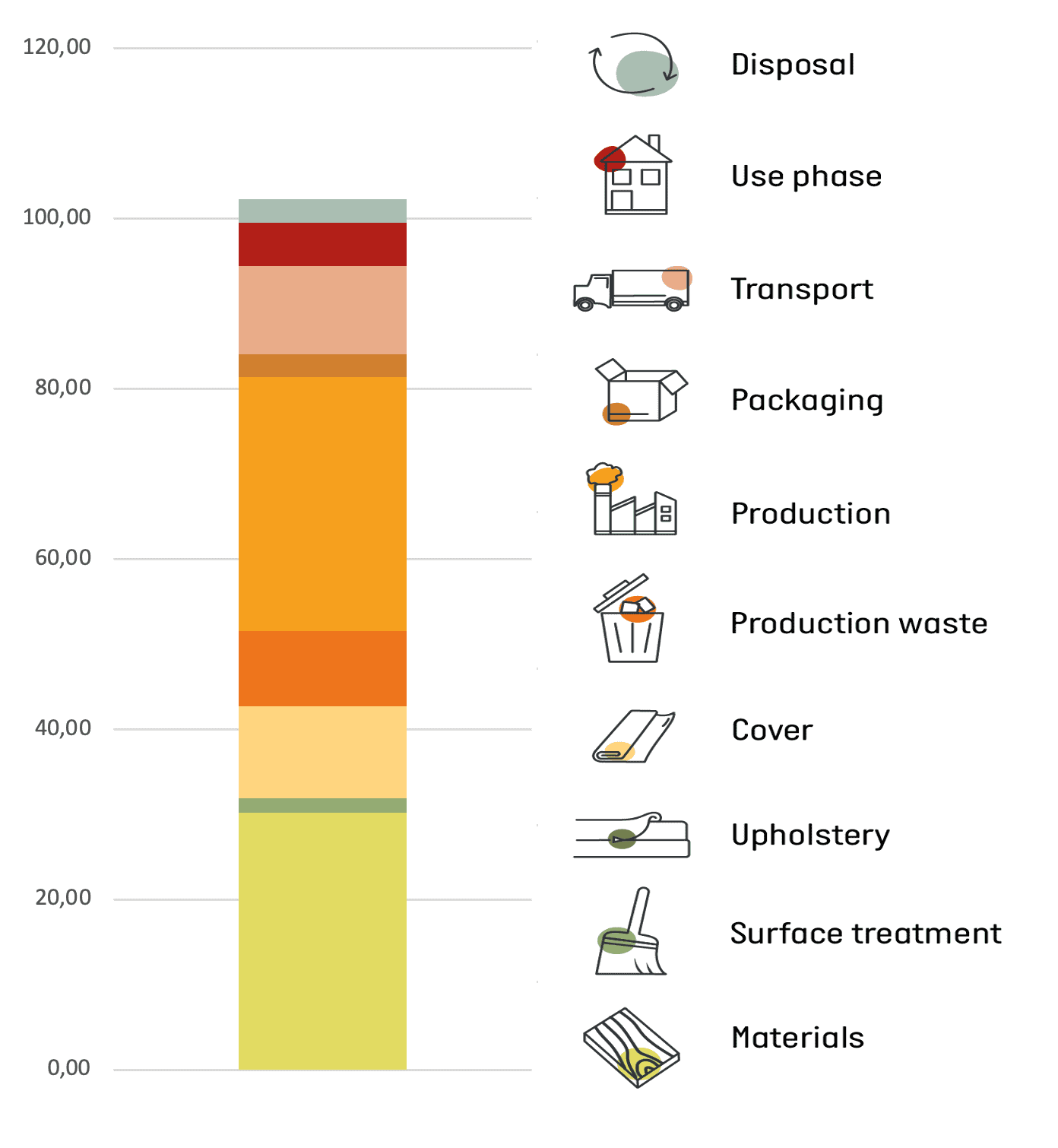

Thomas has named his hollow lounge chair Volume and designed two different steel bases: a five-star foot and a trumpet foot. Both versions have an estimated climate impact of 100 kg CO2eq.

The avoidance of foam and the use of a self-supporting textile are the driving ideas behind this design.

The amount of foam that normally goes into a lounge chair like this would contribute 25% of the total climate impact of the chair. Hence, leaving it out has reduced the result significantly.

The self-supporting textile does however require a quite strong interior frame to keep it suspended during load of a person. Hence, the frame constitutes 25% of this design’s emissions.

Another consideration is ease-of-disassembly which in this case provides a reduction of 11% for being able to separate and recycle the metals at end-of-life.

Photo by Kristine Funch

Explanation of climate bar

The climate bar shows how the emissions from the design are distributed between 10 sources within the product life cycle. Here you can see that the biggest impacts stems from the materials and production. In this case, it is mostly the textile but and wood-based board that carry most of the material emissions. The production emissions primarily come from the spinning and weaving of the textile, because these processes require high amounts of energy.

There are emissions from the use phase on all products, because of the waste that is generated from returned products from consumers.

Assumptions

- The plywood frame of the prototype is quite heavy. Målbar has estimated that a production design will be 50% lighter in weight and has used this as basis for the calculations.

- The actual waste of the SHRINX textile has been calculated so no estimates are needed.

- The plywood boards are assumed to have 15% cutting waste.

- The steel sheet is assumed to have 10% cutting waste.

- Målbar assumes that metals, plastics, and textiles are produced according to the global average unless we know differently. All other materials are assumed to be produced in the EU

- We assume a transport distance by lorry from supplier to warehouse of 1,000 km

- We assume a transport distance from warehouse to final client of 1,000 km

Målbar builds their assumptions on their experience with industrial production and LCA’s on manufacturing companies.

Context

Målbar participates in Danish Design Makers’ 2024 design challenge, The Blind Date experiment where 19 designers and design duos answer furniture briefs from anonymous European furniture companies. The designers use Målbar’s climate screening tool to gain insigths into the climate emissions of materials and production processes, learning about the climate impact of their design choices. Ultimately, the total climate footprint of each design will be calculated and presented at ORGATEC in Cologne on October 22nd-25th 2024.