In recent years, we have seen that the design and furniture industry is undergoing a transformation driven by a growing awareness of resource scarcity and the environmental impact of production. Through conversations with industry professionals and insights from our data, Målbar has observed some trends that we would like to share with you.

Design for disassembly

Design for disassembly is trending in the design industry. It means to design products in a way that makes them easy to disassemble enabling for repairing and replacing broken parts. This increases the chance of prolonging the product lifetime. It also allows for correct sorting of the different materials, so that they can be recycled when we dispose of them, also called the product’s end-of-life.

Designing for easy disassembly is an important step towards a more circular economy, but it requires an additional focus in the design process. For some designs, it can influence the aesthetics and expression a lot while other types of designs are fairly easily compatible with the practice. Especially upholstered furniture that are designed with removable covers can get a characteristic and for some unwanted appearance. On the other hand, wooden tables and chairs can invisibly integrate easy disassembly points.

Flat-pack and knock-down

Being able to flat pack and designing for knock-down often comes as a natural side effect of designing for disassembly. It means that the different parts of a product are packed and shipped in pieces to minimise the volume of the shipment. With flat-packing, you avoid transporting a lot of air and this allows for more products to be loaded in the same space.

Apart from designing for disassembly, there should also be a focus on the shape of the different parts, which should be as flat as possible. Finally, it requires that the product can be easily assembled with ordinary tools and that you provide an assembly guide.

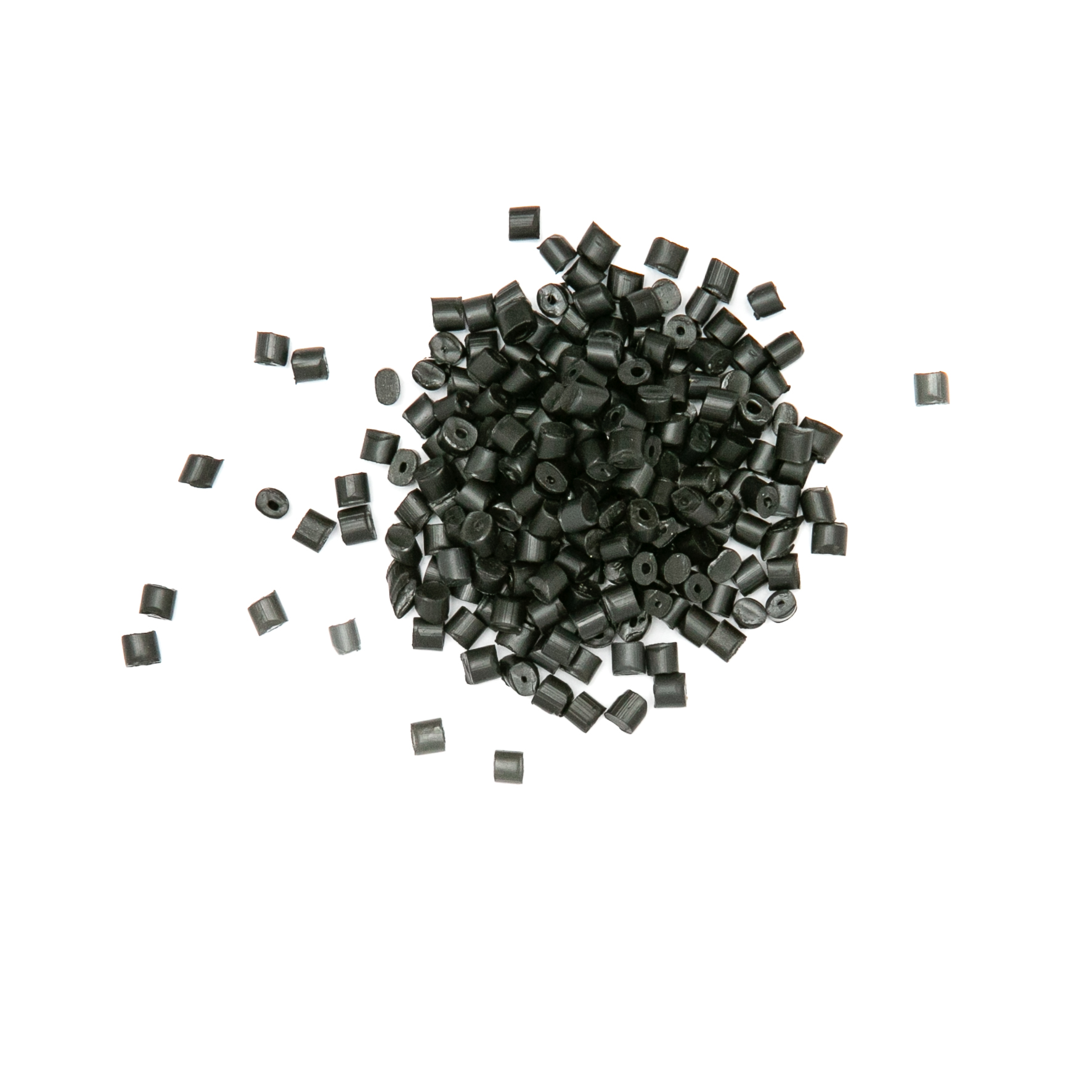

Recycled materials

Using materials that fully or partly consist of materials that have been used in other products and then have been broken down and remade into raw materials. There’s a lot of focus on materials these days, and recycling of materials is an important part of supporting a circular economy. But recycled materials must replace virgin materials before it provides any positive effect. If we just use recycled materials to add products to the massive production we already have, it only makes things worse.

Recycling of materials requires energy, and often, it also requires a lot more additives/reinforcing materials in order to improve the typically lower material quality compared to virgin materials. These additions are often forgotten when praising recycling. Furthermore, mixing recycling materials into your production could result in less recyclable materials in the other end. Learn about the journey of plastics.

Innovative materials

New materials as for example composites of different biodegradable materials often made from leftovers from the food industry (coffee grounds, peels, etc.).

Many designers like to experiment with untraditional materials. And it is important that we investigate and develop better materials. The challenge here is that some might conclude too early that a new material is a lower emitting material without calculating a lifecycle assessment (LCA) on it. Often because their intuition tells them that any biobased material must have a lower environmental impact than for example plastic.

However, many bioplastics are born with higher emissions from being manufactured which overshadows the beneficial effect of their biogenic CO2 emittance. This is because planting, growing, harvesting and processing feedstock for biobased plastic easily constitute higher emissions than the simple process of retrieving crude oil from the ground and its fossil emission at end-of-life. Further, biobased materials are often mixed with additives like glue to secure durability, specific texture, or cohesiveness. Mixing materials can reduce or hinder the ability to be recycled or decomposed.

Finally, but not least, the end-of-life of biomaterials is crucial to how much climate impact they have. If biomaterials end their life being incinerated in power plants, their biogenic carbon end up as CO2 which in a PEF LCA is NOT counted. They also provide heat as a further added benefit. But if they end their life being landfilled – which unfortunately still are the most common in Europe – this oxygen deprived environment makes biomaterial decompose into both CO2 and methane. The CO2 is not counted but the methane causes substantial climate emissions, and these ARE counted. Methane has approximately 30 times more climate impact than the “natural” CO2 decomposition in oxygen rich environment. These facts may surprise some who believes that biomaterials are always a better choice.

Dynamic and flexible designs

Here, we are talking about designs that can be used in various settings and for several purposes. One of the big challenges of our current consumer behaviour is that we live in a world of rapidly changing trends which make us replace our products more often. The new trends make us grow tired of our furniture, our interior design, and then we feel a need for replacing them.

Some designers try to meet this need by creating designs that can change expression or be modified in different ways to meet different needs and wishes. This could be a modular sofa or shelf system that can be combined in different ways, multifunctional furniture like stools that are also tables or benches that are also storage. It can also be upholstered furniture that can easily be reupholstered with new covers. There are no data yet that can support that these initiatives have a positive effect on our consumption patterns, but it seems logical that they could.

The real climate effects of many of these initiatives can be measured with Målbar’s climate screening tool. Contact us today to learn more about what we can do for your green transition.

These are our recent observations and experiences. Trends and tendencies are ever changing and constantly evolving.