Alvilde Holm, exhibition

and furniture designer

Alvilde is board member in Danish Design Makers. She works with exhibition design and furniture design.

Room for interpretation

Alvilde is excited about her brief and her impression of her client is that they are young, openminded, passionate, and fast-paced.

Her task is to design a stackable chair. This is a technical task, and Alvilde is both challenged and thrilled.

I think this is an interesting field to examine. Most people get in touch with stackable chairs on a regular basis, and it is important that such a chair functions well. The brief doesn’t describe any emotional qualities or specific values, so even though it is a functional and technical task, I have the opportunity to work with my own approach to aesthetics and values. I like that.”

Kill your darling

Keeping the design simple and not complicating it too much is a challenge for Alvilde, since she tends to include many functionalities or details in her designs. In the name of reduction, and because of the workshop that Målbar hosted, Alvilde wanted to create a piece of furniture that can change character so that if users get tired of the look, they can modify it. The thing is that lots of people replace their furniture long before it is worn out, because they grow bored by the appearance of it.

“I wanted to make a backrest that could be taken off and turned around, but then it struck me suddenly, that this was me making things too complicated. So, I changed direction and that’s when I began using Målbar.”

New to the reduction theme

Alvilde then decided to make a metal base to which seat and backrest can be added with a variety of materials.

“My approach is not very technical, so I had to overcome opening the tool at first. But when I got started, it felt intuitive, and I find it interesting and even fun to create different scenarios and look up the impact from different materials. The tool has helped me make some vital design choices.”

By investigating different materials in the tool and looking at their climate impact, Alvilde discovered paper cord braiding. She didn’t think of this possibility before she saw the material in the tool, but she was surprised about its low climate impact compared to the other materials she was examining, and she decided to try it.

Paper cord is a durable and lightweight material. I haven’t worked with it before, but I think it is beautiful. I’m experimenting with how little I can use and still create a comfortable seat and back for my chair. I believe it is an interesting alternative to traditional upholstery with a high potential.”

Even though Alvilde hasn’t worked with the climate impact of her designs before, she could see herself using Målbar’s tool in her future work.

“When a component of a design could be made up of many different materials, it makes really good sense to use a climate screening tool to make some of the decisions.”

My design speaks for itself

As a member of the DDM board, Alvilde has taken part in the planning of the blind date experiment. And she really likes the concept. She is not used to work with corporate customers and designing for the contract market, so she likes that her client is anonymous. Even more, she likes the fact that she is anonymous to the client, because it means that her design will speak for itself at the fair.

“My client cannot judge my design on me. Rather, they will judge me by my design and that is a rare opportunity.”

This article reflects the designer’s own opinion and Målbar does not necessarily agree with their statements about materials, processes, etc.

Climate calculations and insights

Alvilde has made two versions of her Danish Cord Chair; one with armrest and one without.

The one with the armrest has a total estimated climate footprint of 19 kg of CO2eq, while the version without the armrest has an estimated total climate footprint of 18 kg of CO2eq.

Alvilde has successfully reduced the climate footprint by making the chair stackable. That has reduced most emissions as transport emissions become high on items of large volume.

She has also successfully minimized the amount of paper cord used for the upholstery. Typically, we see 1 kg of paper cord used for rattan chairs, but Alvilde has succeded in reducing the consumption to only 336 grams.

The chair has potential for reducing climate emissions even further by optimizing the weight of the steel tube frame.

Photo by Kristine Funch

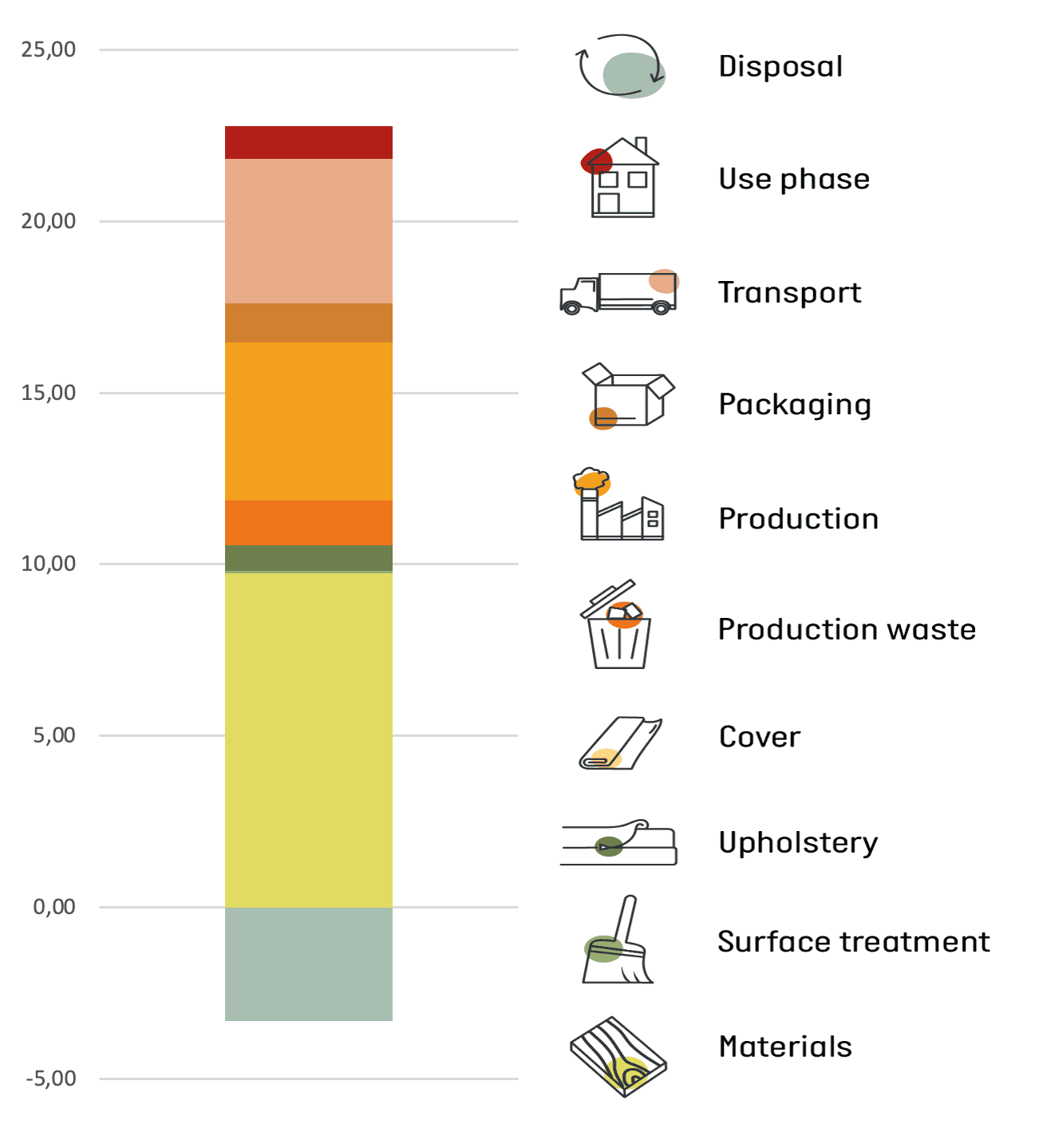

Explanation of climate bar

The climate bar shows how the emissions from the design are distributed between 10 sources within the product life cycle. Here you can see that a major part of the climate impact originates from the steel tube base. However, the design for disassembly results in credit from the disposal phase of the metal components. This can be seen from the disposal part of the climate that lies below zero. Production and transport also carry significant parts of the climate footprint of this design. The transport of air when shipping voluminous products makes the transport less effective and thus increases emissions. The production of metal including welding are energy consuming processes that leave a high footprint.

There are emissions from the use phase on all products, because of the waste that is generated from returned products from consumers.

Assumptions

- Steel tube manufacturing waste is set to 10%

- Paper cord is assumed produced by wood from renewable forestry and with a manufacturing waste of 2%

- We are assuming an average corrugated cardboard box weight of 0.7kg/m2 and extra foam tube and 0.5kg leg piercing protection board of HDF board.

- We assume that metals, plastics, and textiles are produced according to the global average unless we know differently. All other materials are assumed to be produced in the EU

- We assume a transport distance by lorry from supplier to warehouse of 1,000 km

- We assume a transport distance from warehouse to final client of 1,000 km

Målbar builds their assumptions on their experience with industrial production and LCA’s on manufacturing companies.

Context

Målbar participates in Danish Design Makers’ 2024 design challenge, The Blind Date experiment where 19 designers and design duos answer furniture briefs from anonymous European furniture companies. The designers use Målbar’s climate screening tool to gain insigths into the climate emissions of materials and production processes, learning about the climate impact of their design choices. Ultimately, the total climate footprint of each design will be calculated and presented at ORGATEC in Cologne on October 22nd-25th 2024.