In the EU, approximately 10.78 million tons of furniture is discarded every year. Only around 10% is recycled. This is due to the fact that most domestic furniture waste consists of wood-based furniture, upholstered furniture and mattrasses, which are made of materials that are difficult to recycle and only provide a small or no economic and climate benefit to recycle. The recycled 10% is then mostly metal parts, which have a high economic and climate cost to produce from new. This results in a larger benefit for recycling it.

If consumers or waste management were able to easily disassemble furniture into their material sections, it would probably increase the chance of more furniture being recycled. This is one of the good reasons for designing new products for disassembly.

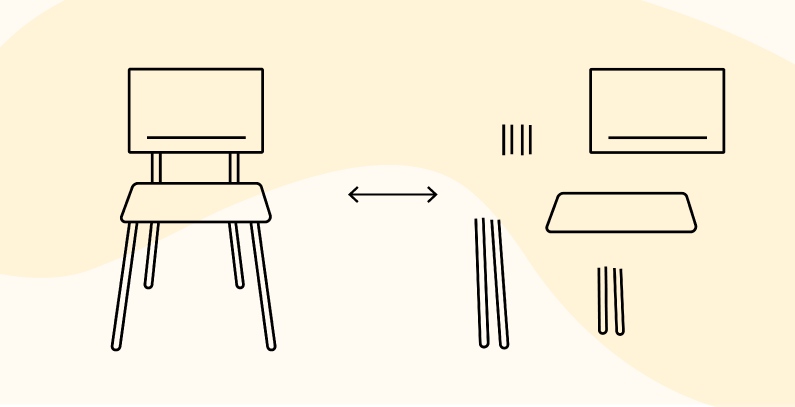

To design a product for disassembly means to incorporate a disassembly function in all assembly points. And must be possible to take it apart in the different materials with simple and ordinary tools*. This enables the materials to be sorted and – depending on material type – recycled. In this regard, it is best to use mono-materials because mixed materials are often difficult or impossible to recycle.

Designing for disassembly also eases repair and replacement of broken parts.

Begin with metal parts

In Målbar’s environmental screening tool, each input material can be marked as designed for disassembly. This means that even though the whole product isn’t designed for disassembly, parts of it might be.

According to the EU Product Environmental Footprint (PEF) standard that Målbar follows, metals are currently the only common furniture materials that have an established and effective recycling system in Europe. Hence, our LCA tool gives credit for designing metal parts to be easily disassembled from the rest of the product. Paper, cardboard, and glass also have well-functioning recycling chains.

Plastic, wood, textile, and upholstery are not materials that are currently recycled in Europe on a large enough scale that allows PEF to give credit for designing these parts for disassembly. However, we hope this will change for the better in the future, so Målbar encourages designing all product parts for disassembly.

Is design for disassembly becoming an industry standard?

Being a part of Danish Design Makers 2024 design challenge, Målbar has learned that design for disassembly is a practice that is getting established in the design industry. All 25 designers participating in the challenge knew about the concept at the beginning of the project and 85% of them have fully or partly designed their product for easy disassembly. This led to many of them succeeding in reducing their product emissions, since they received recycling credit from metal parts. Furthermore, the design for disassembly also led some to design for flat packing which reduces transport emissions.

So, what does it mean to design something for disassembly?

Screw don’t glue is a popular saying within the area. For example, if textile is glued onto the upholstery foam, it is not considered to be designed for disassembly. Furthermore, one must be able to loosen screws and bolts using ordinary screwdrivers and spanners.

Surface coating like paint, lacquer, oil, powder coating, wax etc. cannot be considered as design for disassembly. However, if the component that receives the coating can be recycled with the surface treatment, that may be considered as designed for disassembly.

If two parts are nailed together it is not regarded as designed for disassembly as pulling out nails is often too difficult.

Connects with other EU environmental strategies

Målbar’s experience is that DFD is an increasingly normal practice. It also supports the new EU legislation about consumers right to repair, which will take effect next year 2025. These rules entail that consumers have the right to be able to have their things repaired. Being able to repair one’s things often entails being able to take off the broken part to replace it.

Currently, around 80% of furniture ends its life by being incinerated or landfilled where decomposition in landfills often leads to high methane and carbon emissions. When furniture can be easily disassembled, the chance for sorting and recycling the different materials will increase – and hopefully this will increase the demand for more economic and climate effective recycling systems for wood, plastic, fabrics etc.

Finally, it is essential that you inform your customers and end consumers about the possibility of easy disassembly.

*Source: Annexes 1 to 2, Product Environmental Footprint Method, Dec 2021, page 55