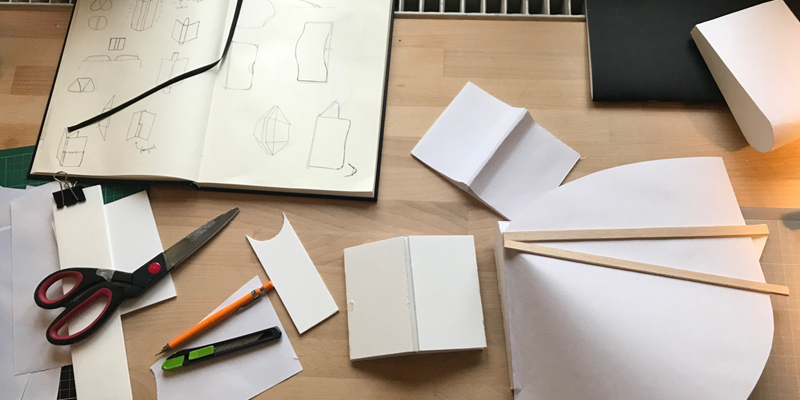

Photo: Bly Studio

Living and working in environments that support our routines, creativity, focus, and motivation is important for humans. Design is a huge part of feeling well and thriving at home and at work.

Humans are creative beings, and we’ll most likely continue to design and create new things.

However, our planet and the earth systems that support life as we know it are under pressure. We need to move away from business as usual and start thinking and designing differently.

We need to consider the environmental footprint of the things we bring into shape. We even have to think about the circumstances of the design process itself. How much paper, and modeling materials do we use?

When we wish to make products with low environmental impacts, it’s essential to consider the whole product life cycle already in the design phase and use that as an inspiration to reduce.

Understanding life cycle assessment

Life Cycle Assessment (LCA) is a way to estimate the climate or total environmental impact of a product or service through all its life cycle phases. The starting point for any product is raw materials that are extracted from nature. Those raw materials are then processed into a product, packaged, sold, used, maybe reused, and eventually disposed of. Through all life phases, a product has an impact on the climate, water resources, soil fertility, human health, etc. – all of which are represented by so-called impact categories. An LCA that is compliant with the Product Environmental Footprint (PEF) rules decided by the EU, considers all impact categories throughout the life cycle of a product and hereby measures its total environmental impact.

This is a challenging task, but Målbar has made it accessible and doable for everyone. With the Målbar screening tool, which is compliant with the PEF standard, it is possible to simulate different product and production scenarios. You can test the emissions from different materials and discover where in the world they can be sourced with the lowest impact.

Ideas for design starting points

Design

- Use a smaller amount of materials – design for lightweight

- Use surface finishes which are durable or easy to renovate in order to increase lifetime

- Design for wear resistance. Avoid denting or chipping edges by rounding them

- Facilitate disassembly of materials in clean fractions and repair e.g. through modular design

- Ensure that surface materials have a good enough wear resistance

Raw materials

- Avoid designing waste in the production. Design for standard dimensions of raw materials

- Use materials and manufacturing methods with low impacts

- Use recycled materials, or left-over materials from your own or other productions

Manufacturing

- Choose manufacturers that use renewable energy sources in their production

- Explore ways to reduce energy consumption and waste

- Avoid toxic chemicals

Distribution

- Reduce packaging weight and use easy-to-recycle packaging (mono-materials)

- Reduce the size of the box if it has a density lower than 300kg/m3

- Reuse packaging materials

- Favor less emitting modes of transportation like ship over airplane and lorry.

- Reduce transport distances

Use

- Design ways for refurbishing the fabrics and surfaces, so that the design can be continuously upgraded.

- Provide information and recommendations like ‘Use organic detergents’ and instructions on how to clean and maintain the product for prolonged lifetime

- Provide instructions on repair, spare part acquisition, and support

End of life

- Facilitate sorting of materials

- Introduce take-back schemes

- Provide recycling centers with instructions

Everyone can play an active role

What is key here, is to understand that it is not enough to focus on reducing the environmental impact from one product life cycle stage or one element of a design. A holistic approach where all aspects of the product life cycle is considered and thought through is crucial. Only this way will we be able to change our business as usual into a responsible approach towards designing, creating, and living.

We all hold a unique position of influence in shaping the future of manufacturing. It’s not just a matter of individual responsibility but a collective effort where every small step count.

Together, we can inspire manufacturers and the entire industry to embrace a more holistic approach.

Designers can act as ambassadors for the green transition by informing their manufacturers about what usually have a large reduction like using renewable energy for manufacturing and avoid creating waste.

Disclaimer: The design ideas are based on the current legislation and knowledge, however, science on the area continuously expands and new knowledge is discovered, which means the content is subject to changes.