The short answer is no! Switching to recycled materials is not necessarily the best method to lower your company’s climate impact. Through LCA’s (Life Cycle Assessments), you can learn where to rethink your production processes and product design. And for an LCA to be effective and precise, it is paramount to dive deep into the production chain and unveil all elements surrounding the production site and the process from start to finish.

If one material would win the title as Biggest Climate Sinner, it would probably be virgin plastic. Some companies ban it from their production because it is viewed as being the biggest polluter in a production chain – or they choose to replace it entirely with some kind of recycled plastic.

And here we want to emphasize that there are many types of recycled plastic, just like there is an enormous number of virgin plastics – many more in fact. The recycled ones are divided into two overall categories: post-consumer recycled plastic and post-industrial recycled plastic. Basically, plastic waste from industrial processes is easier to recycle because it generally is more homogenous and clean, since it is scrap material from production and therefore haven’t been in use.

Through climate screenings and CO2eq calculations on furniture and lifestyle products, Målbar has found that banning virgin plastic and using post-consumer recycled plastic is not necessarily the right change to make if your company aims to reduce its climate emissions.

Virgin plastic vs. post-consumer recycled plastic

The two categories of plastic are very different when it comes to the production process.

Virgin plastics are made from oil and are produced through various chemical processes.

Post-consumer recycled plastics are made from lots of different plastic waste, mostly bottles, bags, containers, and wrapping. The process of sorting and cleaning the plastic waste necessary to be able to recycle it, takes a lot of energy. Later, it is remelted or grounded into small pellets and made into granules that can be used for new plastic products. However, this kind of plastic waste consists of countless different types of plastics, different colors and different alloys. Some of it is recyclable, some of it is not. And often, an amount of virgin plastic needs to be added to secure the quality.

At first glance, the environmental benefits of using post-consumer recycled plastic are many, such as:

- Reduction in use of fossil fuels

- Reduction of plastic waste at landfill sites

- Increase in circularity

What companies tend to forget is that production is not only the mechanical handling of a product, but also the physical space surrounding the production, eg. the factory where the production is taking place; the way the materials are transported; how much waste it generates, etc.

The illustration below gives you an overview of the complexity of the virgin and recycled plastic’s journey to production. The illustration consists of three image slides that provides you with different levels of information. You can view them in full size by clicking on each image.

With this in mind, it becomes clear that the journeys of the materials are quite complicated. One of the biggest and most important contributors to climate emissions in many production processes is the electricity mix on the production site. In some cases, the post-consumer recycled plastic goes through the recycling process in a country with an electricity mix which is more detrimental to the environment than elsewhere.

Therefore, it is important to be aware that switching from virgin plastic produced in a country with a cleaner electricity mix to recycled plastic produced in a country with a more fossil based electricity mix might increase your CO2eq emissions instead of lowering them. It simply might outweigh the climate benefit from using recycled plastic.

When working on a product LCA, all surrounding factors in all product life cycle phases must be taken into account to model and calculate a total environmental impact.

How to assess the environmental impact

Furthermore, when measuring the environmental impact of a product according to PEF standards, the Circular Footprint Formula (CFF) is also included.

The CFF is developed by the European Commission and is part of PEF. It is a tool used to allocate the environmental burdens and benefits of recycled content, recyclability, disposal, and energy recovery. The CFF helps us understand how to credit a certain product in respect to environmental impact. For example, to enhance circularity in both the production and end-of-life phase of products, the CFF determines that the benefit from using recycled materials must be divided in two portions. One that is given when using recycled materials and one that is given if the product is recycled at the end-of-life.

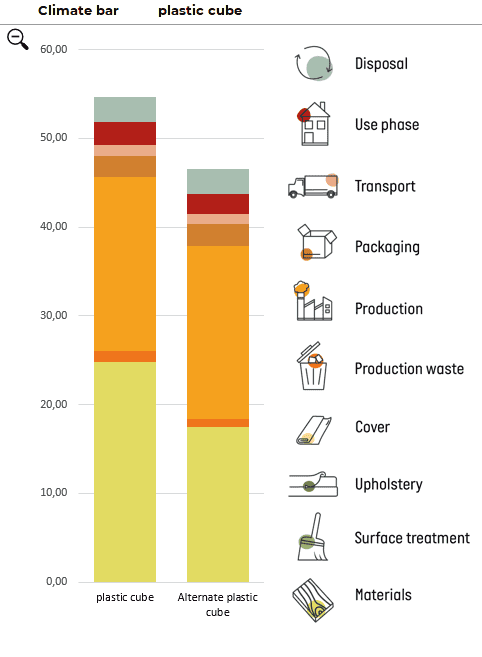

Our screening tool includes all PEF compliant calculation models and is able to show you the climate reductions you will obtain if you interchange your current plastic material with a recycled alternative. Here is an example created with our alternate screening function.

The climate bar on the left shows the emissions from a plastic product made from virgin material. With all other factors being the same, the climate bar on the right shows the climate emissions from the same product but made from post-consumer recycled plastic material. If you would need to change your production location when switching materials, you can also change this in the alternate screening function and see the according results and difference between the two products and production scenarios.

Should you switch to recycled plastic?

Well, it depends. Being able to lower your footprint by switching to recycled plastics, is also determined by the plastic type you want to switch from. Some virgin plastics take more energy to produce than others. For example, many plastics – such as polyethylen (PE), polypropylen (PP), polystyren (PS), polyester (PET ot PETa) and PVC – used for packaging have low emissions and can be produced at an equally low cost. Since the emission is already very low, choosing a recycled version of the material may not have a positive effect on your company’s total CO2eq emissions.

On the other hand, if the material that you seek to replace is for example a more technical plastic type -such as polycarbonat (PC), polyamide (PA), acrylic (PMMA), and acetal (POM) – the benefit of using recycled materials will be much greater, since these types have a high emission. And it will help reduce the overall climate emissions from producing new technical plastic.

There is no ultimate truth on how to do things right

The first step is to understand that sustainable choices not only refer to materials but also to how and where we get our products manufactured, how far we transport them, etc.

The second step is understanding that the energy that goes into recycling materials and manufacturing products is very important. The emissions from this depend on how sustainably this energy is generated.

If you are one of many companies that tend to lean on recycled instead of virgin materials, you may have learned something new now. All the steps through a production chain are equally important when doing a product LCA, and maybe you have untapped potential in lowering your emissions.