Rikke Frost, furniture designer

Rikke Frost graduated as industrial designer from the School of Architecture in Aarhus, where she in 2004 established her own design studio. This is her fifth time exhibiting with Danish Design Makers.

Function above all

Initially, Rikke was a bit puzzled about her brief because it is very short and very open. Rikke works best when she has a specific problem to solve, and not knowing who the customer is adds to the challenge. Her solution has been to further develop the brief and create some requirements herself.

Rikke is serious about function. If a design does not have a function, it is not design to her, it’s art.

Hence, her goal is to make a functional and moveable design that can be adjusted to different purposes and be put together in several modules and thus support a commercial function.

Rikke has taken notice of especially two messages from the reduction workshops hosted by Målbar and a Norwegian waste management company. First, using materials that can be recycled easily, and for which there already exist effective recycling systems is good. Second, minimizing production waste is essential for the product footprint.

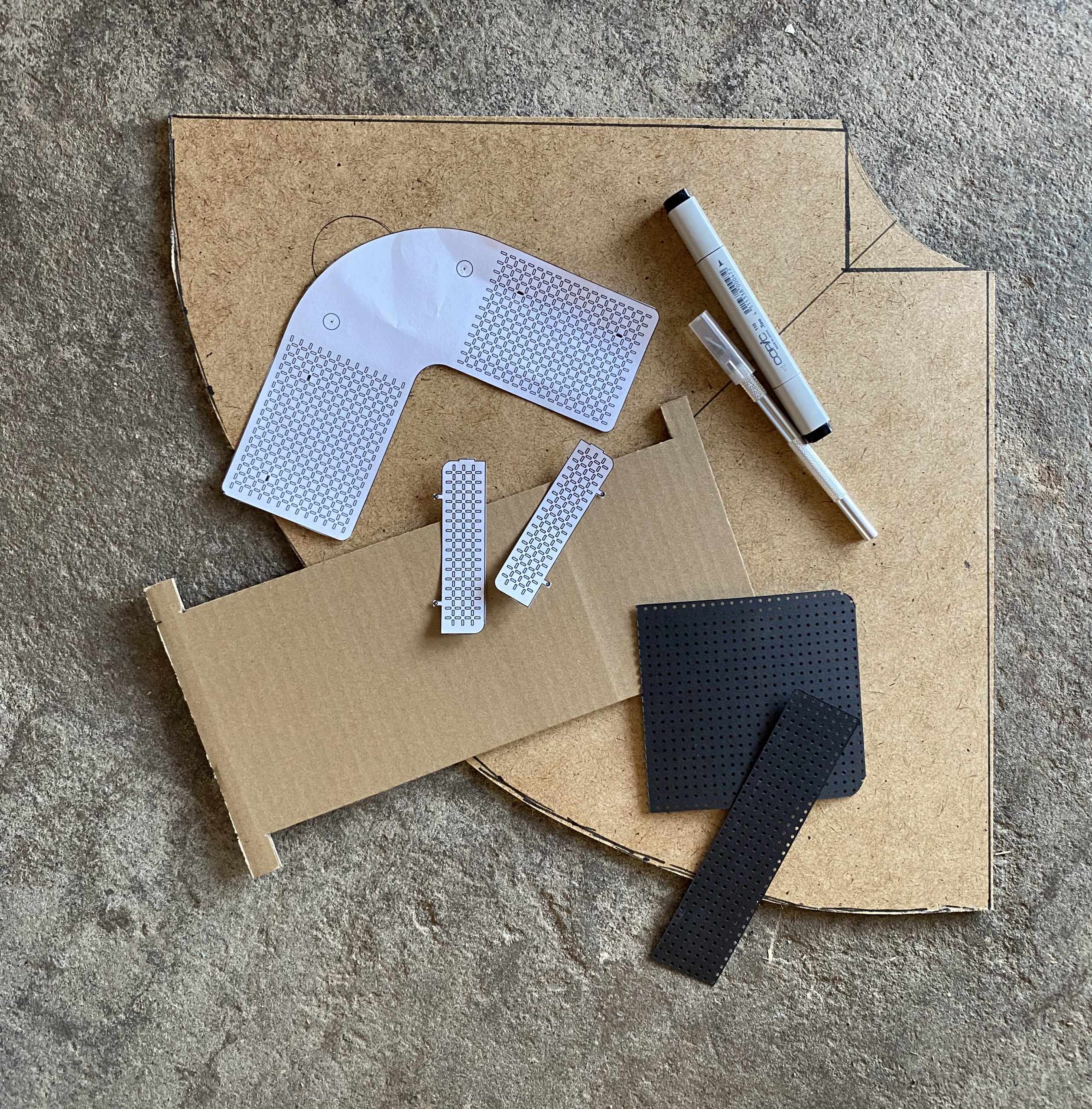

Thus, Rikke has chosen to work with metal. She wants to make a design requiring minimum processing of materials and has chosen to work with metal plates that only need bending and can be assembled with screws. However, she has run into a dilemma.

First, I wanted to work with aluminum because it is a lightweight metal. But to obtain the required strength of the item, I need quite a thick plate. And aluminum is expensive. If I choose steel, I can obtain high strength with a thin plate, but it will be quite heavy.”

Wanting it all

Rikke finds it challenging to limit herself. She wants her design to check all the boxes. She wants it to be stackable, she wants it to fit into standard freight measurements, to have a low climate footprint, and it must be designed for disassembly. And so, she also works on how to present her thoughts about her design at the ORGATEC fair.

Many of my design choices don’t necessarily explain themselves to all people. There are many layers in my decisions. For example, why I have avoided welding, why I don’t use profiles, why I chose to work with metal. This is something I wish to communicate on the exhibition.”

Rikke thinks that the blind date is a cool experiment. She thinks it supports the designers in taking responsibility for starting their designs in the “right” way.

“When I do not know who my customer is, I can create high demands for myself. Even though this can be hard work and sometimes difficult to prioritize, I like that I’m not limited by the company’s ordinary mindset. In this project, I get to show them a finished prototype and I think this makes it easier to engage in a dialogue about the many possibilities.”

This article reflects the designer’s own opinion and Målbar does not necessarily agree with their statements about materials, processes, etc.

Climate calculations and insights

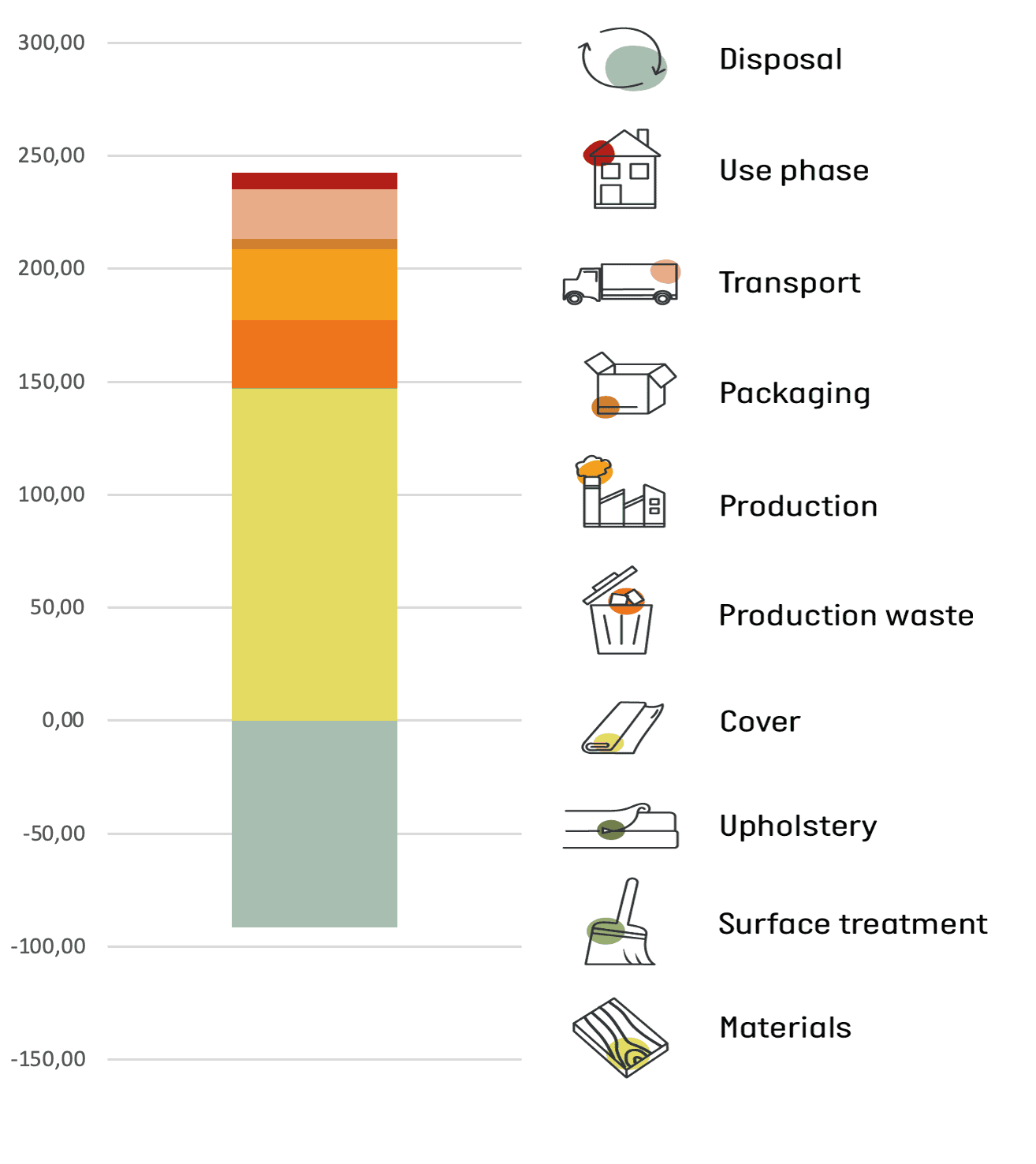

Rikke’s design is called Cardo and has an estimated total climate footprint of 150 kg of CO2eq.

Rikke’s strategy of choosing recyclable materials and making them easy to disassemble has led to emission savings of about 35% of the total climate footprint.

The choice of a perforated metal sheet instead of a construction with metal profiles has not reduced emissions but increased them. This is because this sheet design is quite heavy, weighing around 25 kg. The material from the perforation ends up as (recyclable) waste.

The emissions from the modules can be further reduced. By choosing carbon steel instead of stainless steel and adding paint protection on top, a 13% lower footprint may be obtained.

Photo by Kristine Funch

Explanation of climate bar

The climate bar shows how the emissions from the design are distributed between 10 sources within the product life cycle. Here you can see that the biggest impact stems from the materials, in this case the metals. However, there is also a noticeable part of the climate bar below zero, which means that 91.6 kg of CO2eq are detracted from the final result. This illustrates the credit given for having designed the metal parts for recycling at end of life by making the component easy to be disassembled from the rest of the materials.

There are emissions from the use phase on all products, because of the waste that is generated from returned products from consumers.

Assumptions

- The manufacturing waste of the solid wood components is estimated to be the same as the finished component

- The amount of metal sheet waste is estimated to be 10% + perforated metal waste.

- The amount of metal tube waste is estimated to be 10%.

- Målbar assumes that metals, plastics, and textiles are produced according to the global average unless we know differently. All other materials are assumed to be produced in the EU

- We assume a transport distance by lorry from supplier to warehouse of 1,000 km

- We assume a transport distance from warehouse to final client of 1,000 km

Målbar builds their assumptions on their experience with industrial production and LCA’s on manufacturing companies.

Context

Målbar participates in Danish Design Makers’ 2024 design challenge, The Blind Date experiment where 19 designers and design duos answer furniture briefs from anonymous European furniture companies. The designers use Målbar’s climate screening tool to gain insigths into the climate emissions of materials and production processes, learning about the climate impact of their design choices. Ultimately, the total climate footprint of each design will be calculated and presented at ORGATEC in Cologne on October 22nd-25th 2024.