Søren Duvald, architect

and interior designer

Søren Oskar Duvald was trained as an architect, and graduated from the Royal Danish Academy, Copenhagen in 2010. Søren has been a member of Danish Design Makers since 2018 and has exhibited with them twice before.

Complicated dressed as simple

Søren stands out a little from the rest of the designer group since he is not a classical furniture designer but a conceptual architect in space and furniture design.

I am designing a stackable chair—a simple yet very technical object. The brief also describes a wish for furniture that can create a small, intimate room. I like that about the task.”

Useful climate insights

Søren usually works expressively and often prioritizes form over function, but in this project, he wants to create a simple design that complies with the brief and the reduction theme.

I want to give my design edge and character striving to make it aesthetically sustainable. I have worked with a simple, recognizable silhouette that conveys the use of the chair.”

Søren has decided on a metal base and wooden seat and back. He wants to make the chair as comfortable as possible without needing upholstery. He designs for disassembly and easy repair, supporting repair, recycling, and durability, aligning with responsible practices.

Søren very much appreciates Målbar’s screening tool. He has used it to examine the different tree species, types of metal, and surface treatments when deciding the final details of his design. He also gained a lot from Målbar’s reduction workshop.

“Based on Målbar’s presentation, I gained a lot of extra insights on sustainability. It is interesting to see what my design emits, and I like the idea of showing my client what my design choices mean for the climate footprint.”

This article reflects the designer’s own opinion and Målbar does not necessarily agree with their statements about materials, processes, etc.

Climate calculations and insights

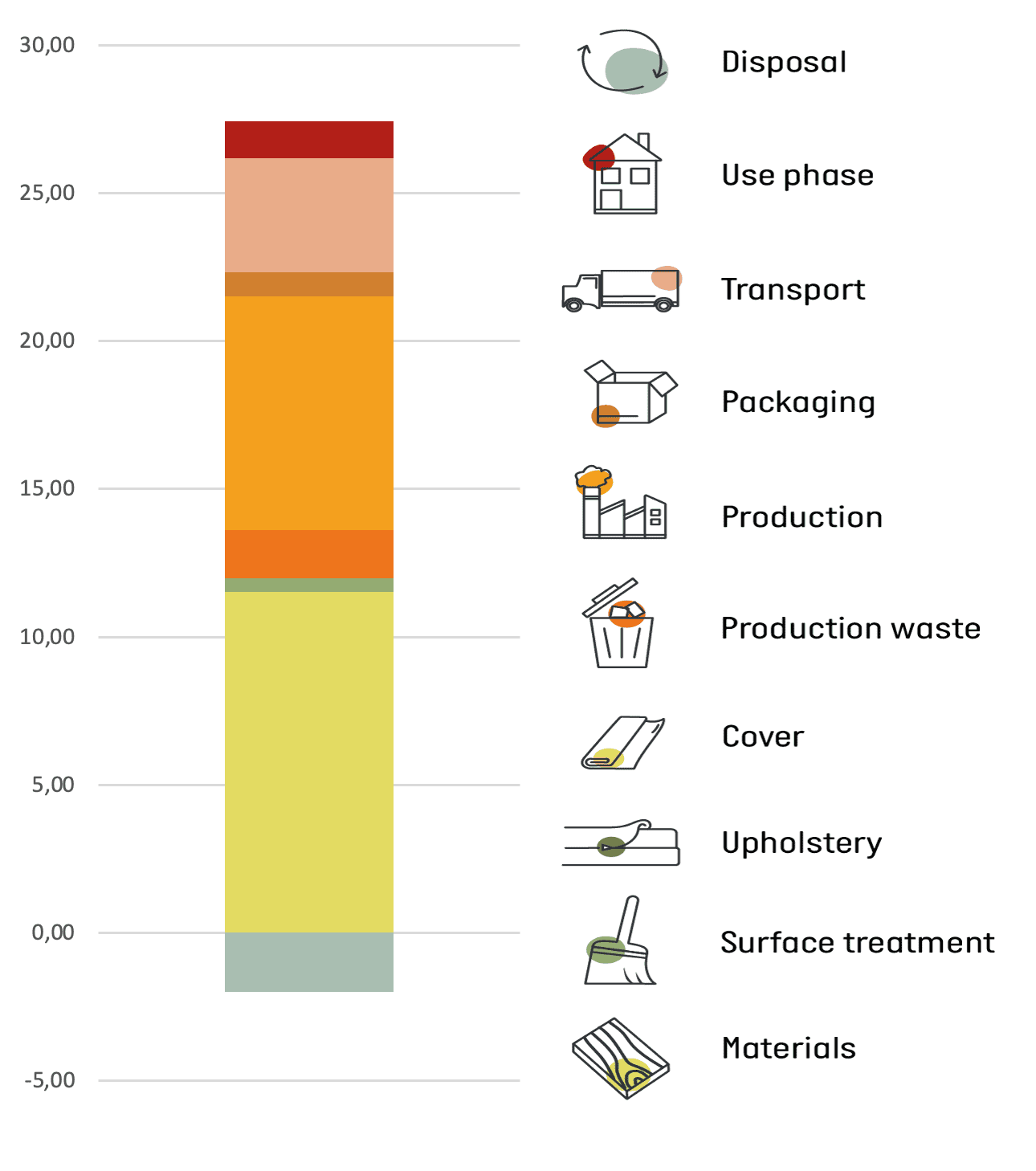

Søren’s stackable chair called Seen Unseen has an estimated total climate emission of 25 kg of CO2eq.

The designer’s focus on using only two materials and ensure easy disassembly benefits the steel tube base’s ability to be recycled at end-of-life. It reduces the total footprint by 17%.

From a climate perspective, the other materials (mostly plywood) do not benefit from this as there is currently no recycling of wooden parts from furniture in the average EU.

Photo by Kristine Funch

Explanation of climate bar

The climate bar shows how the emissions from the design are distributed between 10 sources within the product life cycle. Here you can see that the biggest impacts originate from materials and from production. In this case, it is due to the metal and its manufacturing processes. Furthermore, it is noticeable that a part of the climate bar is below zero. This is the credit given from the recycling of metal at end-of-life, made possible by the design for disassembly. Finally, the transport makes up for a noteworthy part of the emissions, as a lot of air is transported when shipping voluminous products that cannot be flat-packed.

There are emissions from the use phase on all products, because of the waste that is generated from returned products from consumers.

Assumptions

- The plywood components are assumed to have 30% manufacturing waste

- For metal tube components waste of 10% has been assumed.

- We assume that metals, plastics and textiles are produced according to the global average unless we know differently. All other materials are assumed to be produced in the EU

- We assume a transport distance by lorry from supplier to warehouse of 1,000 km

- We assume a transport distance from warehouse to final client of 1,000 km

Målbar builds their assumptions on their experience with industrial production and LCA’s on manufacturing companies.

Context

Målbar participates in Danish Design Makers’ 2024 design challenge, The Blind Date experiment where 19 designers and design duos answer furniture briefs from anonymous European furniture companies. The designers use Målbar’s climate screening tool to gain insigths into the climate emissions of materials and production processes, learning about the climate impact of their design choices. Ultimately, the total climate footprint of each design will be calculated and presented at ORGATEC in Cologne on October 22nd-25th 2024.