Studio FEM, furniture

and interior design

Anders and Sarah are both experienced designers and together, they run Studio FEM. They have been members of Danish Design Makers since 2015 and are members of the board.

Brief with choices

Anders and Sarah are excited about their brief which describes three individual tasks. Initially, they thought they had to answer all three, but they quickly realized that they had to choose one. They are going with the brief that they feel will challenge them and which allows them to design something they believe can make a difference. Their task is to design a piece of storage furniture in recyclable materials.

“Most storage furniture is made by only a few large brands. We think there is room in this category for us to experiment and present our philosophy and values.”

Sarah and Anders noticed in their brief that the client specializes in tables. Therefore, they assume that they have a production of boards, from which they probably produce leftover materials.

Our design can be produced from board materials that could either come from the client’s own production waste or from another local source. Our design is not dependent on rare, new, or unknown materials that might be difficult to get hold of.”

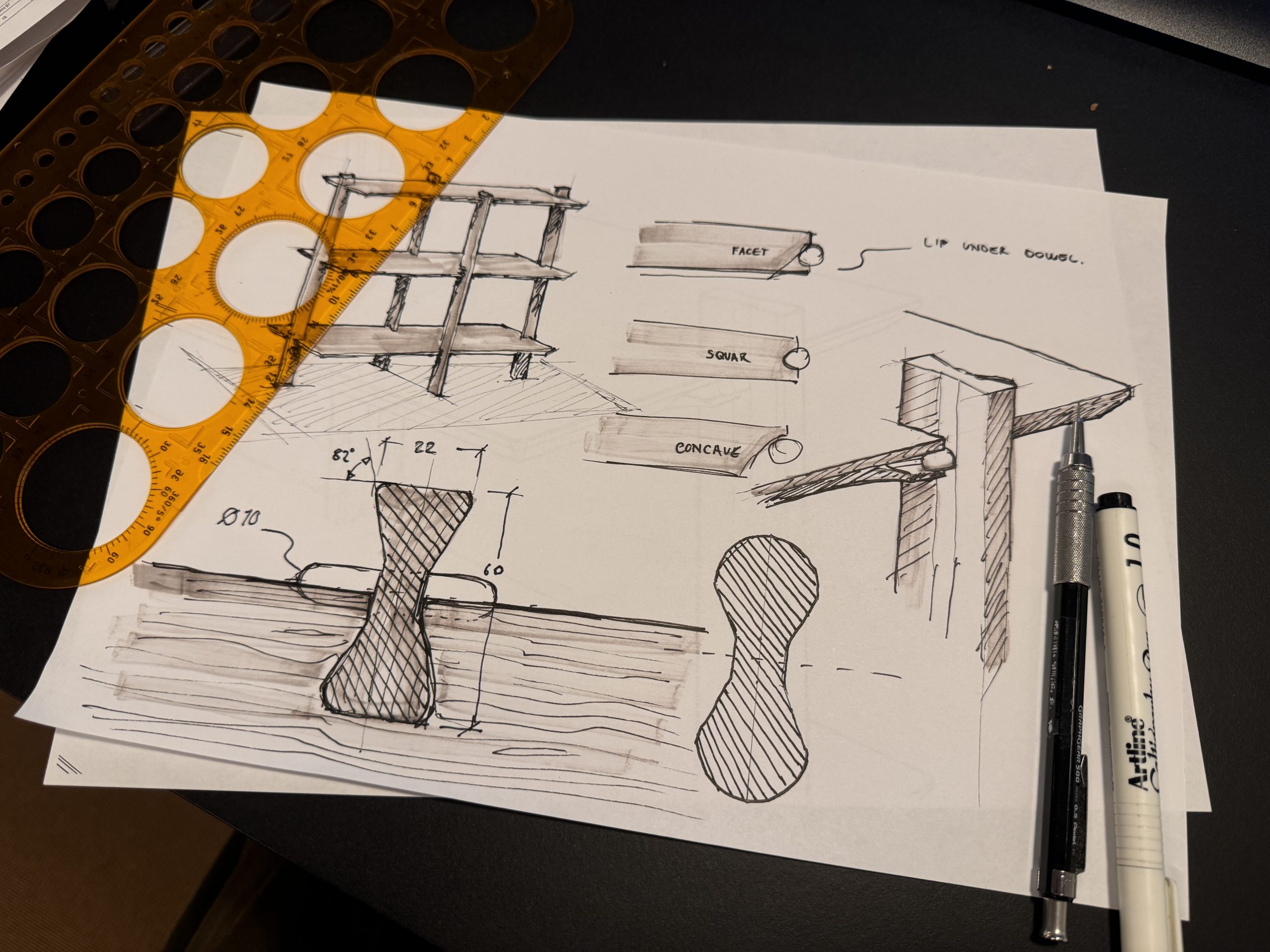

The designers work to create a modular storage element that can be used for several purposes and customized to different needs and environments. They are designing for disassembly so that materials can be reused and recycled.

“We try to answer the brief to the extent that the client hopefully can recognize their brief in our design. We also hope to inspire them with our design and to discover how we can use their own leftover materials in it. Finally, we work to create a design that fits the contract market.”

Complete design

Anders and Sarah are used to participating in DDM’s design challenges, and they appreciate the opportunity to play with their design and challenge themselves in new ways.

They see the reduction theme as the most important parameter for this project.

We want to follow all the way through with this design. We consider not only the materials and production processes, but also the packaging and transportation of both materials and final product. We hope to show a refined design where all product phases have been considered and thus be more attractive to the company.”

The two designers focus on making their product able to be flat packed to avoid transporting air.

They use Målbar’s climate screening tool to figure out how their materials can be processed and which surface treatments they will apply. They want to select production methods that can be completed by local manufacturers, so that the materials don’t need to be transported over long distances.

”We think it is quite interesting to work with Målbar’s tool. It is fascinating to see how different aesthetic expressions influence the climate footprint of the design. On the other hand, it is also sometimes frustrating to discover that a material that we really like has a high climate impact. But then it becomes a matter of priorities, because it is also essential to design something that we believe can be sold and that users want to keep for a long time.”

Reduction increases discussion

Sarah and Anders are liking the reduction theme because it is both interesting and challenging to work with. They think Målbar’s tool challenges their mind set and forces them to review their ideas again and again but also supports them in their decision making.

“As designers, we have our own aesthetic values and favorite materials. So, sometimes we disagree with the tool, because it doesn’t consider all the different parameters that we find important such as the longevity of a design. But we learn a lot and gain many valuable insights working this way.”

Anders and Sarah point out that the reduction premise has fostered many interesting discussions between the participating designers.

We are used to speaking with each other during these yearly design challenges, but this time, we have debated a lot more internally. We have discussed so many subjects, problems, approaches, and argued about right and wrong. It has really been great to talk all these things through.”

Målbar is excited about the designers’ openness and willingness to work so dedicated with this theme, and we appreciate being part of this innovative project.

This article reflects the designer’s own opinion and Målbar does not necessarily agree with their statements about materials, processes, etc.

Climate calculations and insights

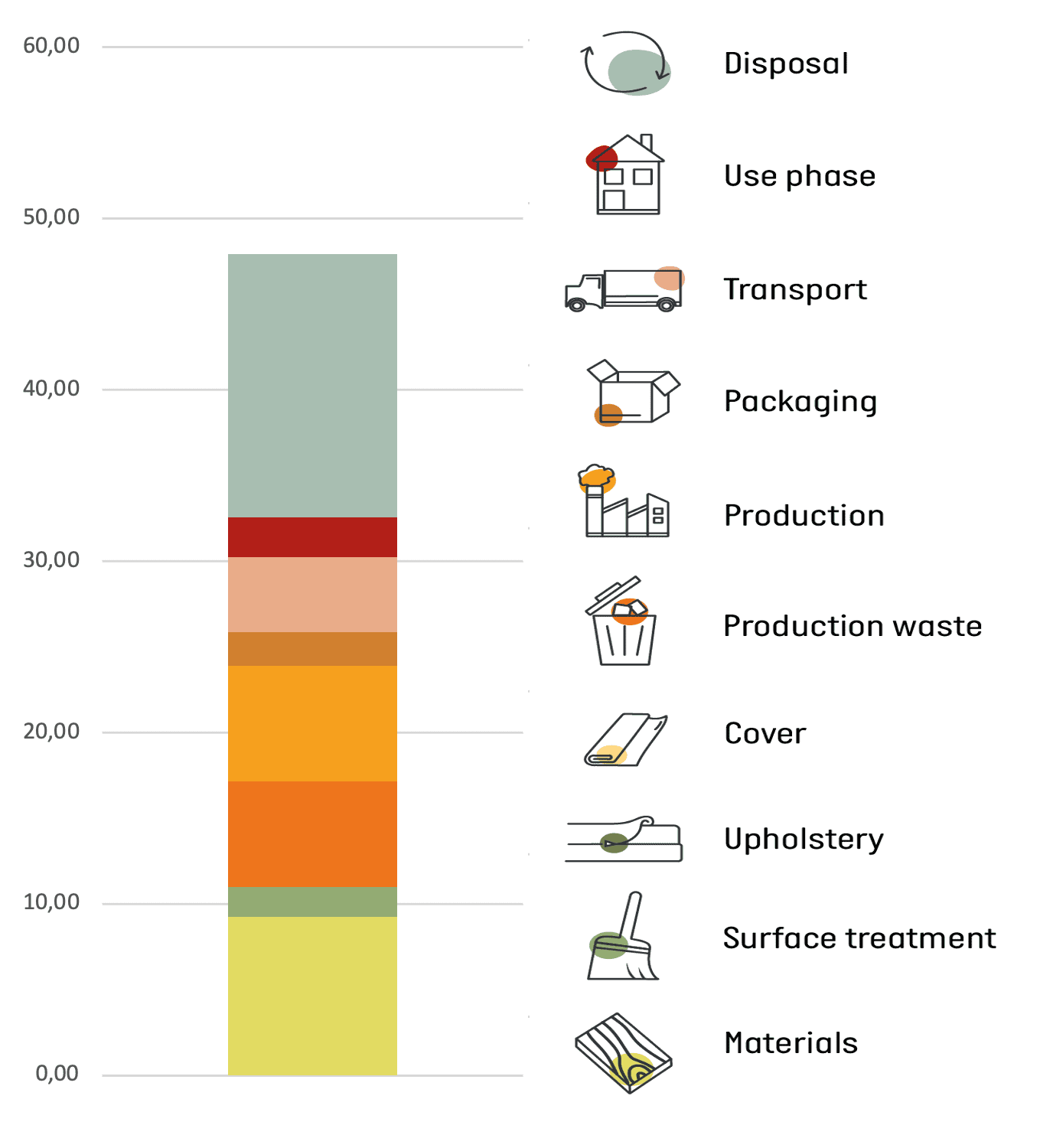

Studio FEM’s modular shelving system called Noend has an estimated total climate emission of 48 kg CO2eq.

The flat packing ability provides nice reductions of approximately 25%.

Another reduction focus on the use of waste materials from the producer’s tabletop production will – if waste material is available – provide a further 16% reduction.

In case that waste materials are not available for the shelving boards there are potential for lowering the footprint by reducing the weight of the wood shelves.

Photo by Kristine Funch

Explanation of climate bar

The climate bar shows how the emissions from the design are distributed between 10 sources within the product life cycle. Here you can see that the major part of the emissions stems from the disposal phase. This is due to the fact that the design is only made of wood, and the biggest emissions from wood happen at end-of-life if the product is landfilled and composted since this has high methane emissions.

There are emissions from the use phase on all products, because of the waste that is generated from returned products from consumers.

Assumptions

- The laminated solid wood components are assumed to have 15% cutting waste.

- We assume that metals, plastics, and textiles are produced according to the global average unless we know differently. All other materials are assumed to be produced in the EU

- We assume a transport distance by lorry from supplier to warehouse of 1,000 km

- We assume a transport distance from warehouse to final client of 1,000 km

Målbar builds their assumptions on their experience with industrial production and LCA’s on manufacturing companies.

Context

Målbar participates in Danish Design Makers’ 2024 design challenge, The Blind Date experiment where 19 designers and design duos answer furniture briefs from anonymous European furniture companies. The designers use Målbar’s climate screening tool to gain insigths into the climate emissions of materials and production processes, learning about the climate impact of their design choices. Ultimately, the total climate footprint of each design will be calculated and presented at ORGATEC in Cologne on October 22nd-25th 2024.