What is the climate impact of electronic products? How can it be calculated?

Our subscribers might have noticed that our electronics section in our screening tool differ from the other material sections because it doesn’t consist of raw materials, but of components. The insides of electronic products are constituted by small electronic parts that consists of many tiny components that are soldered or electrically connected. These items cannot be taken apart to be weighed and measured, and since most customers aren’t able to provide break down on the components and parts constituting the insides of electronic products, we need to use avarage data.

Our estimates are quite conservative and based on average data from the international data base, Simapro EcoInvent and soon also from the EF database.

Electronic products are complicated like a city

Electronics can have many degrees of complexity. There are intelligent electronics in for example cars, where the print boards are very advanced which requires them to have many circuits and hence many layers in order to fulfil their functionality on very little space.

Electronic products are usually made up of a casing or enclosure in plastic or metal which contain electrical boards and some interacting elements like a screen, buttons, keyboard, or microphone all supplied by energy from the grid or a battery.

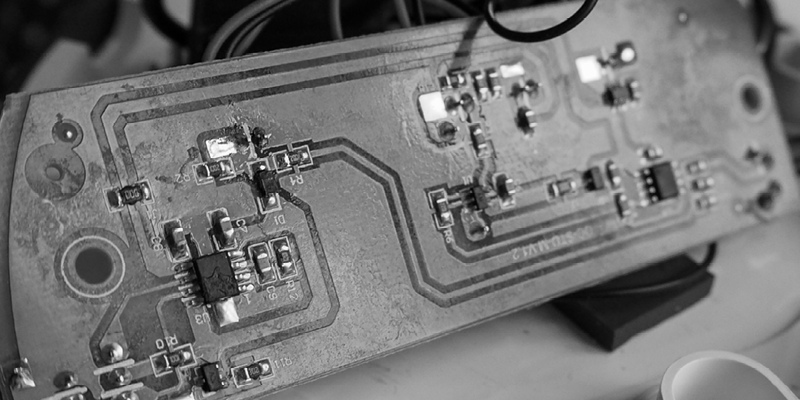

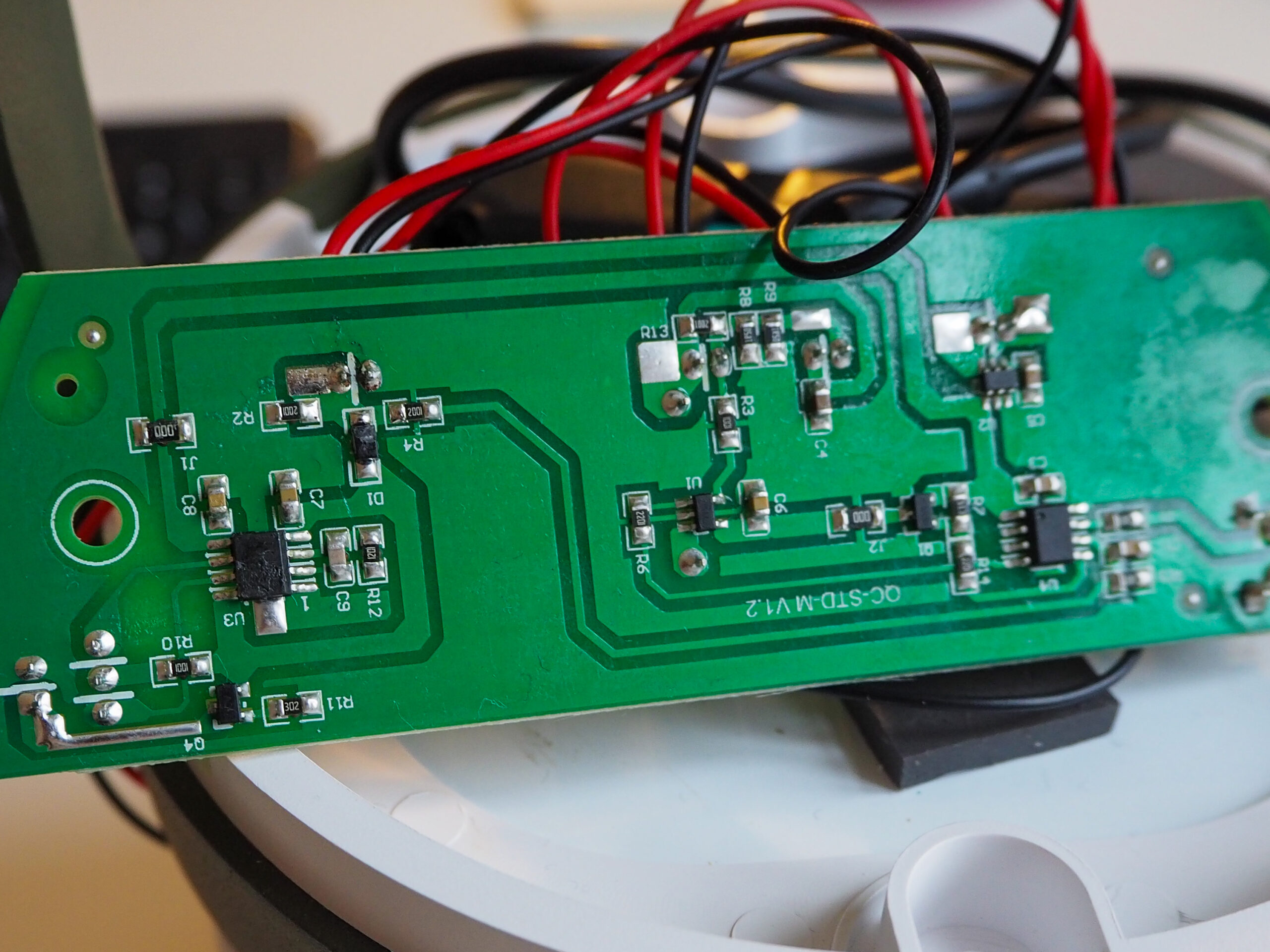

The advanced and intelligent part is the electrical boards which perform all the functions of the product. Electrical boards are also called PCB’s (Print Card Boards). They are like a densely populated miniature scale city where the components are the buildings, and the streets are the electrical connections between them. The electrical impulses flowing between components can be compared to traffic moving between buildings.

The boards are usually made of glass fiber glued together with epoxy and the tiny components attached are mostly made of electro ceramics. The most advanced of these are the electrical brains called IC’s (Integrated Circuits) which has a core of electrical circuits embedded in a piece of silicon. This again has a protective plastic cap on. These components adhere to the board through metals like copper, tin, gold, platin, silver, or other rare metals that often require large amounts of energy to extract.

Standard unpopulated print boards are produced in large sheets and cut out into smaller pieces for individually shaped boards.

The sustainable perspective

Way too many electronic products go to waste and are not properly reused nor recycled. Furthermore, many people just leave their old electronics in a drawer at home, because they don’t know what to do with it. And many sort their electronic waste wrong when they finally get rid of it. So, what might we do to make the electronics industry less polluting?

Making electronics that consume less electricity when in use is an important task which already have showed good results on many products. Many electronic products – like cell phones – are now consuming such small amounts of energy that the production of the electronic product itself has a higher footprint than the use of it.

It is also possible to reduce the climate impact of the production phase. The energy consumption when producing electronics is very high. A substantial energy reduction at the scale we need is not realistic. But it is possible to reduce the climate impact from production significantly by powering the manufacturing plants with green energy instead of fossil fuels. Unfortunately, most electronic production is located in Asia, making it difficult for Danish companies alone to do anything about it. It would require a massive and collective force to make the manufacturers switch to renewable energy sources.

Reuse

Another solution is to create and support a larger reuse market. Already in Denmark, there are at least three companies, that repair and update used smartphones, laptops and computers and resell them with guarantee. And this is a good start.

For a study, we received some test products from a customer, so that we could get familiar with the insights of battery powered lamps. And what we first discovered was that we needed to break the lamp to get to the electronic parts, meaning they are not easily replaced if they break down. And they are not easily reused if other parts of the product breaks.

If lamp manufacturers started to design and produce for disassembly, they could implement a take back system allowing them to reuse the electronic parts in new lamps.

Recycling

There are factories in Germany that recycle electronic components like print boards, and it would be quite interesting to further examine how much electronic waste is being recycled, by whom, and for what purpose. Since these components contain a fairly high amount of rare metals, it could make a big positive climate impact to recycle it.

However, it would still be better to reuse and prolong the usage of electronic products by repairing.

Not to forget, many electric appliances – especially lighting – emit most of their total emissions during their use phase. So, it is still relevant to focus on how you can produce energy efficient products.

And then there are all the other ways a product impact the environment. For example, electrical components contain relatively high amounts of rare metals, thus they eat into our finite resources. Soon, our tool will be able to show the effect of this alongside the effects on all of the 16 environmental impact categories.

So stay tuned and see what we can do to support your climate goals.